How to Achieve GS1 Compliance for End-to-End Supply Chain Traceability

At a time of rapidly moving products across national boundaries and an even more convoluted global supply chain, the need to satisfy the desire for transparency, security, and authentic products has never been greater. To businesses, tracking, tracing, and verifying any product from origin to destination is an end benefit rather than a luxury. It has become a source of competitive advantage. It is here that GS1 supply chain standards become relevant, as this is a worldwide agreed-upon standard through which end-to-end supply chain traceability may be achieved.

The GS1 standards, which entail globally unique identifiers, structured data sharing, and barcode labelling systems, assist the business in making sure that all content within the supply chain can be traced and verified, audited, and secured. With effective implementation, GS1 compliance not only passes the regulatory requirements but also enhances brand reputation, solves inefficiencies, and guards consumers from counterfeit products.

This is an end-to-end guide on GS1 compliance, elements of GS1-borne traceability, and how exposing such concepts into action by using solutions, such as Origin by Acviss, makes it much easier and economical to integrate such standardisations into businesses.

What is GS1 and Why Does it Matter?

GS1 is a worldwide nonprofit organisation that designs and maintains a system of supply chain standards across industries. These standards are an inter-business and inter-governmental common lingo used internationally to make automatic identification and capturing of data by the barcode and using digital identifiers.

The core of GS1 supply chain standards is:

- Global Trade Item Number (GTIN): unique product identification

- Data Matrix Barcode: a 2D compact scan-readable code that is used to encode product and supply chain data.

- Serialised Product Identification: Every unit of a product is assigned a distinctive serial ID.

- GS1-128 barcodes: These are read to capture other details about a product, including batch numbers or expiry dates.

- Electronic Product Code Information Services (EPCIS): Information sharing of traceability data between trading partners.

GS1 compliance can help companies realise product authentication GS1, minimise inefficiencies, enhance the accuracy of data information, and create assurance among all stakeholders in the supply chain.

Step 1: Define Your Traceability and Compliance Objectives

The companies must identify what they want before embarking on the GS1 journey. Altogether, end-to-end supply chain traceability is not universal; rather, it depends on person-to-person, business-to-business, and industry relationships. The common goals are:

- Compliance with governmental regulations (e.g., DSCSA, EU FMD, VA)

- Enhancing the recall of products in terms of speed and accuracy

- Increasing the accuracy of inventory management

- Combating counterfeiting and diversion

- Certifying the use of a product verification mechanism to consumers

By identifying your traceability goals, you will be in a position to understand the extent to which your implementation of GS1 should be implemented, the technology to be used, and how you should carry out serialisation.

Step 2: Register and Obtain a GS1 Company Prefix

The first technical procedure to achieve GS1 compliance is to obtain a GS1 Company Prefix in the country where you intend to complete it. This special attribute number is the foundation connecting the formation of the GTINs and other GS1 identifiers.

When you get your Company Prefix, you can start generating:

- GTIN of every product version

- SSCCs are used to monitor shipping containers and pallets

- GLNs (Global Location Numbers) are to be used to determine physical destinations such as warehouses or factories.

These identifiers guarantee that all products and stuffing places within your supply chain can have one-of-a-kind identities with universal acceptance- the establishment of end-to-end identity in your supply chain.

Step 3: Assign GTINs and Implement Data Matrix Barcodes

Having the Company Prefix in use, it is time to assign a Global Trade Item Number (GTIN) to all products and packaging levels. This makes the products unique and not duplicated in channels of sale or geographically.

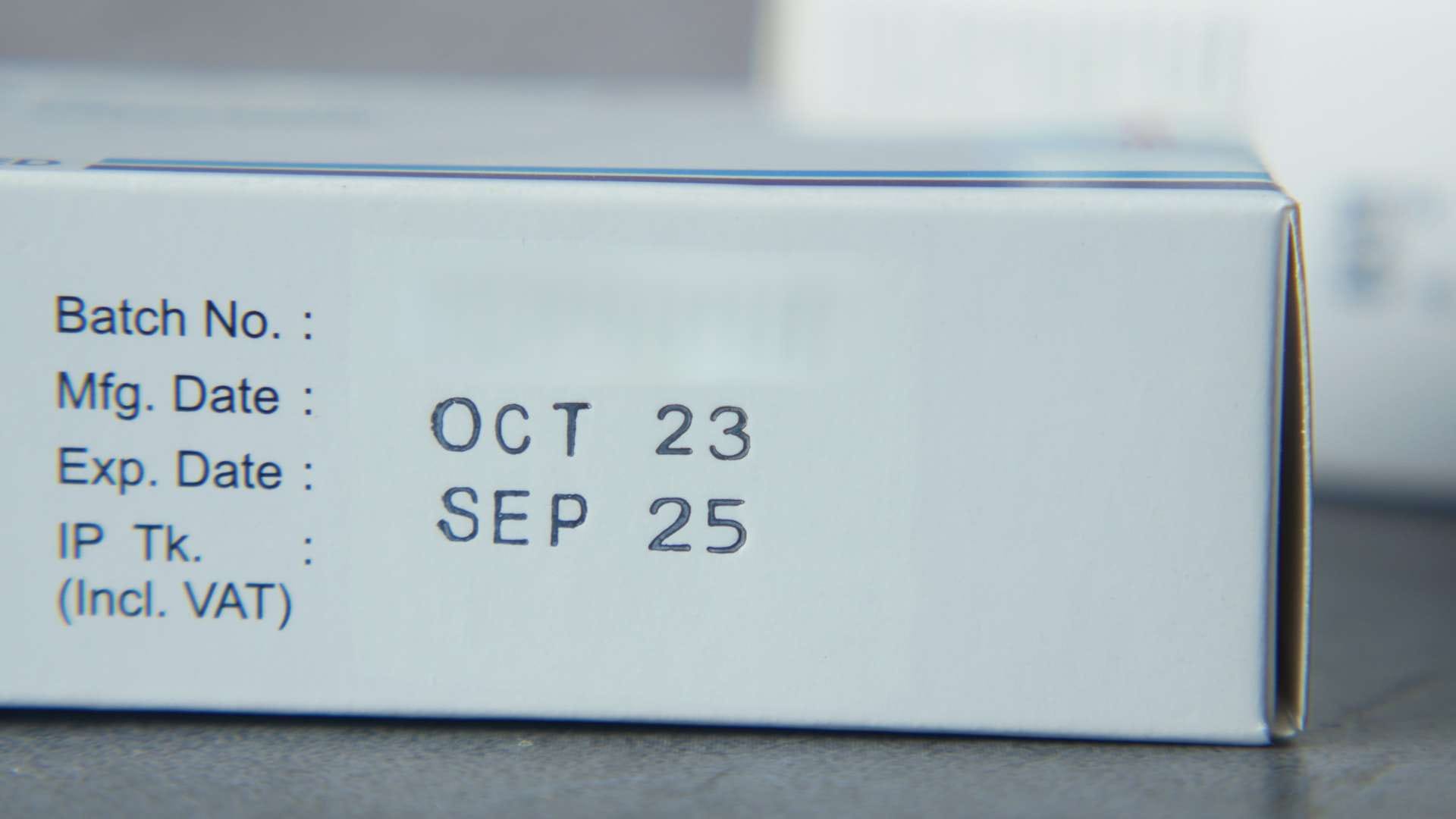

To scan such GTINs, you must encode them as barcodes. In the majority of product-oriented applications, the Data Matrix Barcode, a high-capacity 2D code capable of having large amounts of data (which includes):

- GTIN

- Serial number

- Batch/lot number

- Expiry date

Step 4: Implement Serialised Product Identification

The next level of traceability is serialisation, where each product item has its own serial number. This is not merely establishing the type of products (through GTINs), as it also enables you to track the path of each particular item through its journey, all the way to its consumption.

Serialised product identification supports:

- Item-level traceability

- Recall of a product with pin-point accuracy

- GS1-enabled systems product authentication GS1

- Inventory and delivery real-time checking

In such sensitive industries as the pharmaceutical sector, serialisation is not only advisable but also a requirement. Regulations such as the Drug Supply Chain Security Act (DSCSA) and iVEDA in India stipulate serialised data in order to eliminate counterfeit medicine and safeguard human health.

Step 5: Digitally Track and Share Supply Chain Data

EPCIS enables companies to record critical events- e.g., the date and time a product was manufactured, shipped, received, or sold. That can be done in different, structured, and interoperable forms.

This data can be used to:

- Track and trace the product in real-time

- Audit supply chain activities

- Alert stakeholders to anomalies or delays

- Enable efficient recall if necessary.

To be GS1 compliant, all this data should be structured with GS1 identifiers and exchanged between partners of the trade in a secure and standardised manner.

Step 6: Integrate with Existing Business Systems

Implementation of the GS1 standards should be integrated into your systems of operation to achieve maximum efficacy. Such systems can consist of:

- Enterprise Resource Planning (ERP) systems

- Warehouse Management Systems (WMS)

- Manufacturing Execution Systems (MES)

- Supply chain and logistics software

To remain traceable, barcodes have to be read, and information has to be checked in real time. Automation, accuracy, and efficiency are created by seamless integration.

Nevertheless, creating an internal ecosystem like this one will be costly and labour-intensive. It is at this point that turnkey solutions such as Origin by Acviss come to the utmost use.

How Origin by Acviss Enables GS1 Compliance

Origin by Acviss is an anti-counterfeit and traceability cloud-based platform and is specifically tailored to assist organisations in achieving and sustaining GS1 compliance easily. Origin is created to be scaled and secure, combining GS1 identifiers and newer technologies such as blockchain, machine learning, and mobile authentication.

Key Capabilities of Origin:

1. GTIN and Serialisation Engine

Origin enables brands to automatically create GTINs and provide each unit, packaging level, or batch with a unique serial number. This allows grain-level trace and complete serialisation of products.

2. Smart Barcode Integration

Origin makes use of the data matrix barcode and QR codes, which are capable of containing GTINs, batch numbers, expiration dates, and unique identifiers. They can be printed on the packaging or applied digitally so they can be easily scanned along the supply chain.

3. Product Authentication and Consumer Engagement

The customers will be able to scan the barcode through the Origin mobile interface to affirm the authenticity of the product. The scans retrieve information through the GS1-compliant records to provide real-time product verification.

4. Blockchain-Powered Audit Trails

All of these scans, as well as transactions, are permanently captured in the blockchain. Integrity, traceability, and readiness for regulatory audit: Since data integrity cannot be tampered with in this infrastructure, in the case of forensic or regulatory audits, they are always ready.

5. Supply Chain Visibility Dashboards

Real-time dashboards and analytics provide companies with a high-level, centric view of product flow, product bottlenecks, product risks of fraud, and recall at a global market level.

6. Plug-and-Play Integration

Origin can be integrated with ease into the current ERP, WMS, and POS systems. It is made to operate across industry verticals like pharmaceuticals, FMCG, electronics, and apparel.

Companies are not only able to adopt the GS1 standard by using Origin but also make traceability a competitive advantage.

Benefits of GS1 Traceability in Logistics and Operations

The use of GS1 standards produces numerous layers of value in operations, logistics, marketing, and compliance:

1. Real-Time Visibility

Monitor all product units in transit to ensure better planning, accuracy of deliveries, and use of resources.

2. Fraud and Counterfeit Prevention

The ability to authenticate the product with serialised data allows it to be authenticated at each level securely. This aids in identifying counterfeited, grey-market or diverted products.

3. Regulatory Readiness

You do not have to make last-minute rushes in the face of audits and government-imposed track-and-trace programs.

4. Customer Trust

Through transparency tools such as Origin, consumers can confirm authenticity and have the traceability to find Origin, establishing long-term brand loyalty.

5. Efficiency and Cost Savings

Get rid of paper, minimise returns, and make your logistics fast and easy by automating and scanning barcodes.

Final Thoughts

Making the supply chain resilient, brand protection, and customer trust is not a checkbox but a sign of long-term dedicated investment. With the increasingly strict global regulations and the risk of counterfeiting becoming more advanced, deployment of the GS1 standards is becoming a must for contemporary business strategy.

Such solutions as Origin by Acviss offer a rapid, scalable, and secure method of realising an end-to-end traceable supply chain in line with international GS1 best practices. Origin features such as serialised product identification, data matrix barcode scanning, and real-time product authentication capabilities will help organisations develop a safer, more intelligent, and transparent supply chain.

With data, trust, and security being the keys to success in an era where only the most secure can be considered most successful, GS1 traceability enabled by tools such as Origin is no longer a requirement. It's leadership.

Get in touch with our experts and discover how Origin enables complete visibility in the supply chain.