Brand Protection and Traceability in Southeast Asia: A Practical Guide for Manufacturers

Southeast Asia has become one of the most strategically important manufacturing and consumption regions in the world. From electronics and automotive components to food, pharmaceuticals and apparel, the region’s factories supply both local markets and global brands. At the same time, Southeast Asia has emerged as a hotspot for counterfeiting, grey market diversion and fragmented supply chains that make product verification difficult.

For manufacturers operating across ASEAN, brand protection and supply chain traceability are no longer optional safeguards. They are essential business capabilities tied directly to product safety, customer satisfaction, regulatory compliance and long-term brand trust.

This guide is written for manufacturers who want clarity rather than jargon. It unpacks the real risks in Southeast Asia, explains how anti-counterfeiting and product authentication work in practice, and outlines how traceability can be built into modern supply chains without disrupting operations.

Why Southeast Asia Faces Unique Brand Protection Challenges

ASEAN is not a single market. It is a network of ten countries with different regulatory maturity, enforcement capacity and consumer behaviour. Rapid industrialisation has outpaced the development of unified brand protection frameworks.

Several structural realities define the region:

- Highly decentralised manufacturing, with extensive use of contract and third-party manufacturers

- Large informal retail networks alongside organised trade

- Strong cross-border trade flows within ASEAN

- High price sensitivity among consumers, which counterfeiters exploit

- Uneven enforcement of trademark and IP protection laws

Counterfeit goods in Southeast Asia are not limited to luxury items. Everyday products such as cosmetics, spare parts, medicines and packaged foods are frequently targeted, directly impacting product safety and brand credibility.

The Real Cost of Counterfeiting in ASEAN Markets

Counterfeiting is often discussed as a revenue loss issue. In reality, the damage runs deeper.

For manufacturers, counterfeit and diverted goods lead to:

- Erosion of brand trust and brand authentication failures

- Increased warranty claims and service costs

- Legal exposure due to unsafe or substandard products

- Weakening of trademark protection and IP ownership

- Reduced effectiveness of customer engagement programmes

For consumers, counterfeit products raise serious product safety concerns. In sectors such as pharmaceuticals, food and automotive components, the consequences can be fatal.

ASEAN governments recognise the problem, but enforcement varies widely by country, creating gaps that counterfeit networks actively exploit.

Country-Specific Risk Landscape in Southeast Asia

Thailand

Thailand has a strong manufacturing base and relatively mature IP laws. However, counterfeit goods continue to circulate through informal markets and online channels. Grey market imports and parallel trading remain major challenges for brands, particularly in electronics, cosmetics and automotive parts.

Manufacturers operating in Thailand often face a disconnect between compliant factory output and what eventually reaches the end customer. This makes product verification at downstream touchpoints critical.

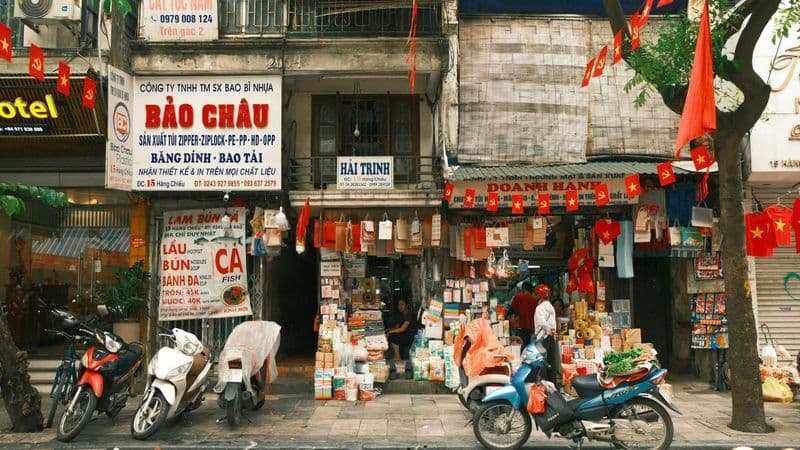

Vietnam

Vietnam is one of the fastest-growing manufacturing hubs in Southeast Asia. Its rapid scale-up has created opportunities, but also risks. A large number of small and mid-sized suppliers operate with limited digital traceability, increasing vulnerability to substitution and unauthorised overproduction.

Counterfeit consumer goods, footwear, apparel and electronics accessories are common. Trademark protection exists, but enforcement can be slow, particularly for foreign brands without local visibility.

Indonesia

Indonesia is a vast archipelago with complex logistics networks. Monitoring product movement across islands is inherently difficult. Informal retail dominates many regions, making brand authentication at the point of sale challenging.

Counterfeiting in Indonesia affects food products, pharmaceuticals, automotive components and FMCG goods. Brands that rely solely on legal enforcement often struggle to scale protection effectively.

Why Traditional Anti-Counterfeiting Measures Fall Short

Many manufacturers still rely on outdated approaches to brand protection.

Common limitations include:

- Static holograms that are easily replicated

- Centralised serialisation systems that do not extend beyond factories

- Manual audits that are reactive rather than preventive

- Legal enforcement without supply chain visibility

These methods may demonstrate compliance, but they do little to support real-time product authentication or customer-facing brand verification.

In Southeast Asia, where products move quickly through layered distribution networks, anti-counterfeiting solutions must work at scale and across borders.

The Role of Supply Chain Traceability in Brand Protection

Supply chain traceability connects physical products to digital records across their lifecycle. When implemented correctly, it enables manufacturers to answer critical questions:

- Where was this product manufactured

- Which batch or line did it come from

- Has it been diverted, duplicated or tampered with

- Is it safe and compliant for consumption?

Traceability is no longer limited to regulated industries. Even FMCG and consumer goods brands are adopting traceability to protect brand authentication and improve customer satisfaction.

In ASEAN markets, traceability also helps manufacturers manage complex supplier ecosystems and demonstrate accountability to regulators and partners.

Product Authentication and Verification at Scale

Product authentication goes beyond identifying counterfeits after the fact. It allows brands to verify authenticity at multiple touchpoints, including factories, warehouses, distributors, retailers and end consumers.

Effective product verification systems share three characteristics:

- They are difficult or impossible to clone

- They do not require specialised hardware

- They integrate seamlessly into existing packaging and workflows

This is where non-cloneable technologies play a critical role. Unlike traditional labels, non-cloneable identifiers rely on inherent physical randomness that cannot be duplicated, even by the original manufacturer.

When paired with digital systems, they create a robust layer of brand verification that works across borders and channels.

Using Digital Traceability Without Disrupting Operations

One concern manufacturers often raise is operational disruption. Implementing traceability should not slow down production or increase per-unit costs beyond reason.

Modern anti-counterfeiting solutions are designed as modular layers rather than heavy system overhauls. They integrate with existing ERP, LIMS and supply chain systems, allowing manufacturers to start with high-risk product lines and scale gradually.

A practical example is the Origin by Acviss, which embeds non-cloneable labelling technology into packaging and enables real-time end-to-end track and trace across markets. Rather than replacing existing systems, it acts as a digital trust layer that connects physical products to secure verification records.

Such approaches are particularly relevant in Southeast Asia, where supply chains span multiple regulatory and infrastructural environments.

Customer Engagement Through Product Verification

Brand protection is no longer an internal-only function. Increasingly, consumers play a role in brand authentication.

Simple, frictionless product verification builds trust and encourages customer engagement. When customers can verify authenticity easily, brands gain valuable insights into product movement, market demand and potential diversion points.

In ASEAN markets, where mobile penetration is high, customer-facing product authentication also supports:

- Improved customer satisfaction

- Faster identification of counterfeit hotspots

- Stronger post-purchase brand relationships

This shifts brand protection from a defensive cost centre to a value-generating capability.

Trademark and IP Protection in ASEAN

Trademark protection and IP protection remain foundational. However, legal registration alone does not prevent misuse.

ASEAN countries follow different legal frameworks and timelines for trademark enforcement. Brands that rely solely on reactive legal action often struggle to keep pace with fast-moving counterfeit networks.

Traceability and product authentication strengthen IP protection by providing evidence. When brands can demonstrate where and how counterfeits enter the market, enforcement becomes more targeted and effective.

In this sense, technology complements legal protection rather than replacing it.

Building a Practical Brand Protection Strategy for Southeast Asia

For manufacturers operating in ASEAN, an effective strategy includes:

- Risk mapping by product category and country

- Layered anti-counterfeiting solutions rather than single-point controls

- Non-cloneable product authentication for high-risk SKUs

- Supply chain traceability across manufacturing and distribution

- Customer-facing product verification to close the loop

The goal is not absolute control, but meaningful visibility and faster response.

The Future of Brand Protection in Southeast Asia

Southeast Asia will continue to grow as a manufacturing and consumption powerhouse. With that growth comes increased scrutiny on product safety, origin and authenticity.

Manufacturers that invest early in traceability and brand authentication will be better positioned to scale confidently, protect their trademarks and build long-term trust with customers and regulators alike.

Brand protection in this region is no longer about reacting to counterfeits. It is about designing supply chains that make counterfeiting unviable.

Conclusion

Brand protection and traceability in Southeast Asia demand a practical, region-aware approach. Anti-counterfeiting solutions must work across borders, integrate with existing systems and support real-world product verification at scale.

By combining supply chain traceability, non-cloneable product authentication and customer engagement, manufacturers can move from compliance-driven protection to trust-driven growth.

Interested to learn more about strengthening your brand protection and traceability strategy in Southeast Asia? Get in touch with us.