The Rising Threat of Counterfeit Electronic Components And How to Detect Them

Counterfeit electronic components have quietly become one of the most dangerous risks in modern manufacturing. These fake parts, often indistinguishable from genuine ones, infiltrate supply chains, compromise product safety, and threaten entire industries—from healthcare and aviation to telecommunications and defence.

What makes this problem especially concerning is that counterfeit parts can pass quality checks unnoticed, only to fail catastrophically in the field. In an interconnected world where even a single faulty chip can bring down critical systems, detecting counterfeit electronic components has never been more urgent.

The Growing Problem of Counterfeit Components

A Global Supply Chain Challenge

Global trade in counterfeit goods is estimated to exceed $1 trillion annually, with electronics accounting for a significant share. As demand for devices and components continues to surge, counterfeiters exploit every gap in the supply chain to push fake or repurposed parts into circulation.

These counterfeit components are often produced using substandard materials, or they’re rebranded versions of outdated or defective parts. Despite being visually identical to authentic components, they lack the reliability and durability required for real-world use.

Why Counterfeiting Persists

The incentives are massive. Counterfeiters enjoy high profits with relatively low risks, especially in regions with weak enforcement or limited traceability standards. Common tactics include:

Parts alteration: Removing genuine markings (“black topping”) and reprinting new logos or date codes.

E-waste repurposing: Extracting components from discarded devices and reselling them as new.

Remanufacturing defective parts: Fixing or repainting rejected components to mimic authentic ones.

Each of these methods makes detection harder and amplifies risks for manufacturers and end users alike.

Consequences of Using Counterfeit Components

Counterfeit parts may pass functional tests initially, but under real-world stress, they often fail causing equipment breakdowns, system malfunctions, or even safety hazards.

In sectors like medical devices, aviation, and defence, the failure of a single counterfeit part can lead to catastrophic outcomes. Beyond safety, such incidents inflict enormous financial and reputational damage, with recalls, lawsuits, and lost trust affecting entire product lines.

How to Detect Counterfeit Electronic Parts

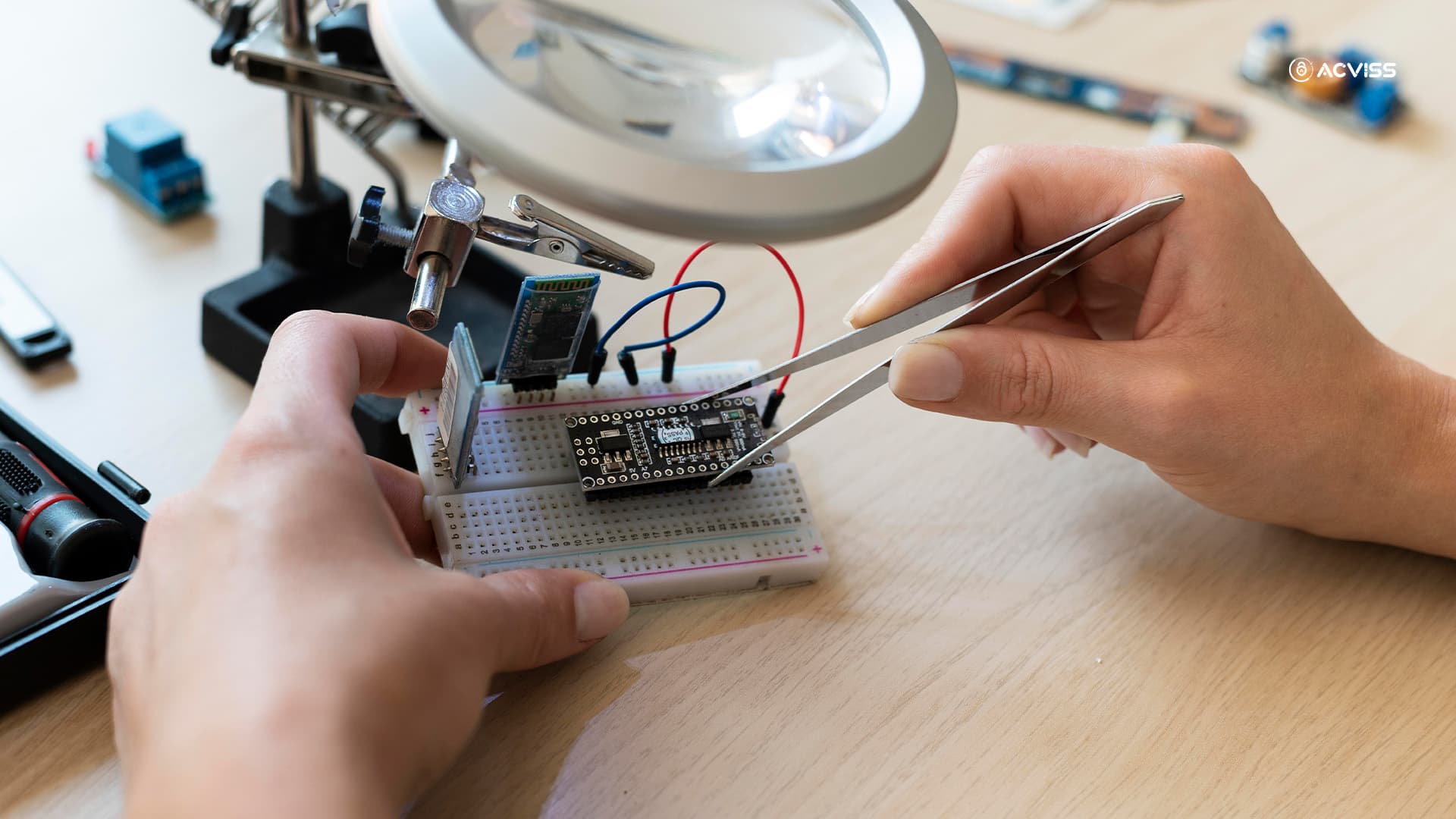

As counterfeiters become more sophisticated, detection methods must evolve beyond surface-level checks. Here are the most effective techniques currently in use:

1. Visual Inspection

While simple, visual inspection remains the first line of defense. Inspectors look for telltale signs such as inconsistent logos, misspelled markings, or unusual font sizes. However, many modern counterfeits are so well made that visual checks alone are no longer sufficient.

2. X-Ray Tomography

This non-destructive testing (NDT) method examines the internal structure of a component. By comparing internal images with known authentic parts, manufacturers can spot anomalies like missing wire bonds, inconsistent die sizes, or voids that indicate tampering.

3. Scanning Acoustic Microscopy (SAM)

SAM technology detects internal modifications, such as black topping or hidden etching. By using ultrasonic waves, it can reveal layers beneath the surface that would otherwise remain invisible to the naked eye.

4. Destructive Testing (Decapsulation)

When doubts persist, destructive testing provides definitive evidence. It involves removing the component’s outer casing using chemical acids to expose internal structures and verify authenticity. Though it destroys the sample, it’s the most conclusive method available.

5. Serialization and Traceability Systems

One of the most reliable ways to prevent counterfeit parts from entering the supply chain is through serialization and digital traceability. Each component or batch can be assigned a unique digital identity—such as a secure QR code or encrypted serial number—allowing real-time verification at every stage of movement.

Solutions like Origin and Uniqolabel enable manufacturers to tag, track, and authenticate components from production to assembly, ensuring that only genuine parts enter the production process.

Benefits of Advanced Counterfeit Detection

1. Enhanced Product Reliability

By filtering out counterfeit parts before assembly, manufacturers can ensure consistent performance and reduce the risk of product recalls.

2. Improved Supply Chain Transparency

Traceability solutions provide visibility across the entire component journey—helping identify weak links, unauthorized distributors, and fraudulent suppliers.

3. Stronger Customer Trust and Brand Integrity

When buyers and partners can verify the authenticity of each component, confidence in the brand strengthens, leading to long-term loyalty and reduced compliance risk.

4. Reduced Financial Losses

Early detection prevents costly downstream failures. Investing in inspection and traceability systems saves far more than the losses caused by counterfeit-related recalls or downtime.

Securing the Future of Electronics Manufacturing

As electronic systems grow more complex, traditional quality checks alone can’t ensure authenticity. The path forward lies in integrated, technology-driven detection systems—combining physical testing, digital traceability, and automated verification.

With tools like Certify (for product authentication) and Origin (for end-to-end traceability), manufacturers can verify the legitimacy of each part in real time—protecting both performance and reputation.

Counterfeit electronic components aren’t going away anytime soon, but with a proactive, multi-layered defence strategy, their impact can be drastically reduced.

FAQs

1. Why are counterfeit electronic components so hard to detect?

Because counterfeiters replicate the physical appearance of genuine parts and sometimes reuse actual components, they can easily pass standard visual or functional tests.

2. What industries are most affected by counterfeit parts?

Electronics, aerospace, automotive, defense, and healthcare sectors are particularly vulnerable because of their reliance on high-precision components.

3. How can digital traceability help prevent counterfeits?

By assigning each component a unique, verifiable identity, digital traceability ensures that every part can be authenticated and tracked from manufacturer to end user.

4. What’s the most effective detection method?

A combination of non-destructive testing (like X-ray and SAM) and serialization-based digital verification offers the most comprehensive protection.

Counterfeit electronic components threaten not just profits, but people’s safety. With end-to-end traceability and product authentication technologies, manufacturers can detect and eliminate fakes before they cause harm.

Explore how digital traceability and authentication can strengthen your manufacturing integrity with solutions like Certify, Origin and Uniqolabel