Enhancing Supply Chain Traceability to Combat Counterfeit Auto Parts

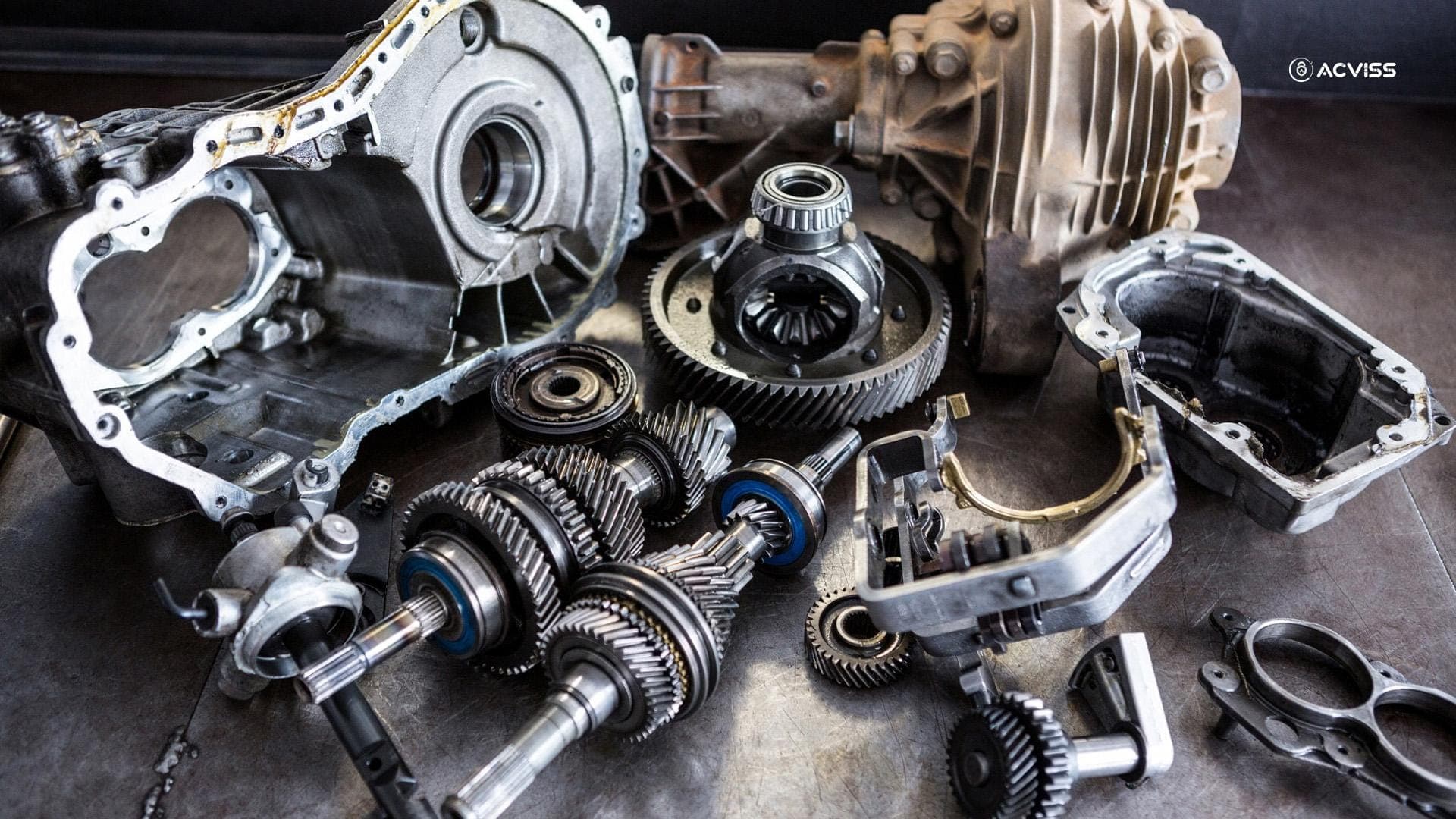

The automotive industry is facing an escalating battle against counterfeit auto parts. From brake pads to airbags, fake components are infiltrating global supply chains, endangering lives, damaging brand reputations, and costing manufacturers billions of dollars annually. According to industry reports, the counterfeit auto parts market is estimated to be worth $45 billion globally, with thousands of substandard components slipping into legitimate distribution networks every year.

With the complexity of modern supply chains—often spanning multiple countries, suppliers, and regulatory environments—traditional tracking methods are proving inadequate. Counterfeiters exploit these vulnerabilities to introduce fake products that are indistinguishable from genuine parts. The solution? Advanced supply chain traceability mechanisms that leverage cutting-edge technology to ensure authenticity, enhance regulatory compliance, and safeguard consumers.

This guide explores the rising threat of counterfeit auto parts, the role of supply chain traceability, and the latest technologies that are transforming how manufacturers and suppliers combat fraud.

The Growing Crisis of Counterfeit Auto Parts

Counterfeit auto parts aren’t just a financial problem; they’re a life-threatening hazard. Unlike genuine parts that undergo rigorous quality testing, counterfeit parts are often made from inferior materials and fail to meet safety standards. This can result in brake failures, engine malfunctions, airbag failures, and other catastrophic consequences.

Why is the Market for Fake Auto Parts Growing?

Several factors contribute to the rapid rise of counterfeit components:

- Complex Global Supply Chains: Modern supply chains involve multiple suppliers, distributors, and intermediaries, making it difficult to trace a part’s origin.

- Weak Regulatory Enforcement: Many countries lack stringent anti-counterfeiting laws or fail to enforce existing regulations.

- Online Marketplaces: E-commerce platforms enable counterfeiters to sell directly to consumers with little oversight.

- Cost-Driven Decisions: Auto repair shops and buyers, looking to cut costs, may unknowingly purchase counterfeit parts.

- Technological Advancements: Counterfeiters have become increasingly sophisticated, creating near-perfect replicas of genuine parts.

To combat this crisis, supply chain traceability must evolve, integrating real-time monitoring, authentication, and verification systems to detect and eliminate fake components.

The Role of Supply Chain Traceability

Supply chain traceability refers to the ability to track the journey of a product from raw materials to the end consumer. Strengthening traceability will enable automakers and suppliers to verify authenticity, detect counterfeit infiltration, and improve recall management.

Key Benefits of Enhanced Traceability

- Authenticity Verification: Ensures every part used in vehicles is genuine and sourced from authorised suppliers.

- Regulatory Compliance: Helps manufacturers adhere to global safety and quality standards such as ISO 9001, IATF 16949, and UNECE R90.

- Efficient Recall Management: Allows quick identification of defective or counterfeit components for targeted recalls.

- Enhanced Consumer Trust: Reduces the risk of vehicle failures due to counterfeit parts, boosting customer confidence in brands.

- Operational Efficiency: Improves inventory management and supplier accountability.

Technologies Revolutionising Supply Chain Traceability

1. Blockchain: Creating a Traceable Record of Authenticity

Blockchain technology offers a decentralised, tamper-proof ledger that records every transaction within the supply chain. Each auto part can be assigned a unique digital identity, ensuring transparency from manufacturing to installation.

How Blockchain Helps Prevent Counterfeiting:

- Provides an immutable record of each part’s journey.

- Enables instant verification by manufacturers, distributors, and consumers.

- Prevents unauthorised modifications or counterfeit entries.

Blockchain adoption is increasing as smart contracts automate verification processes, reducing manual intervention. These contracts can trigger alerts when inconsistencies are detected, improving fraud prevention. Tokenisation is being explored, where each part is assigned a unique digital token, preventing duplication or tampering.

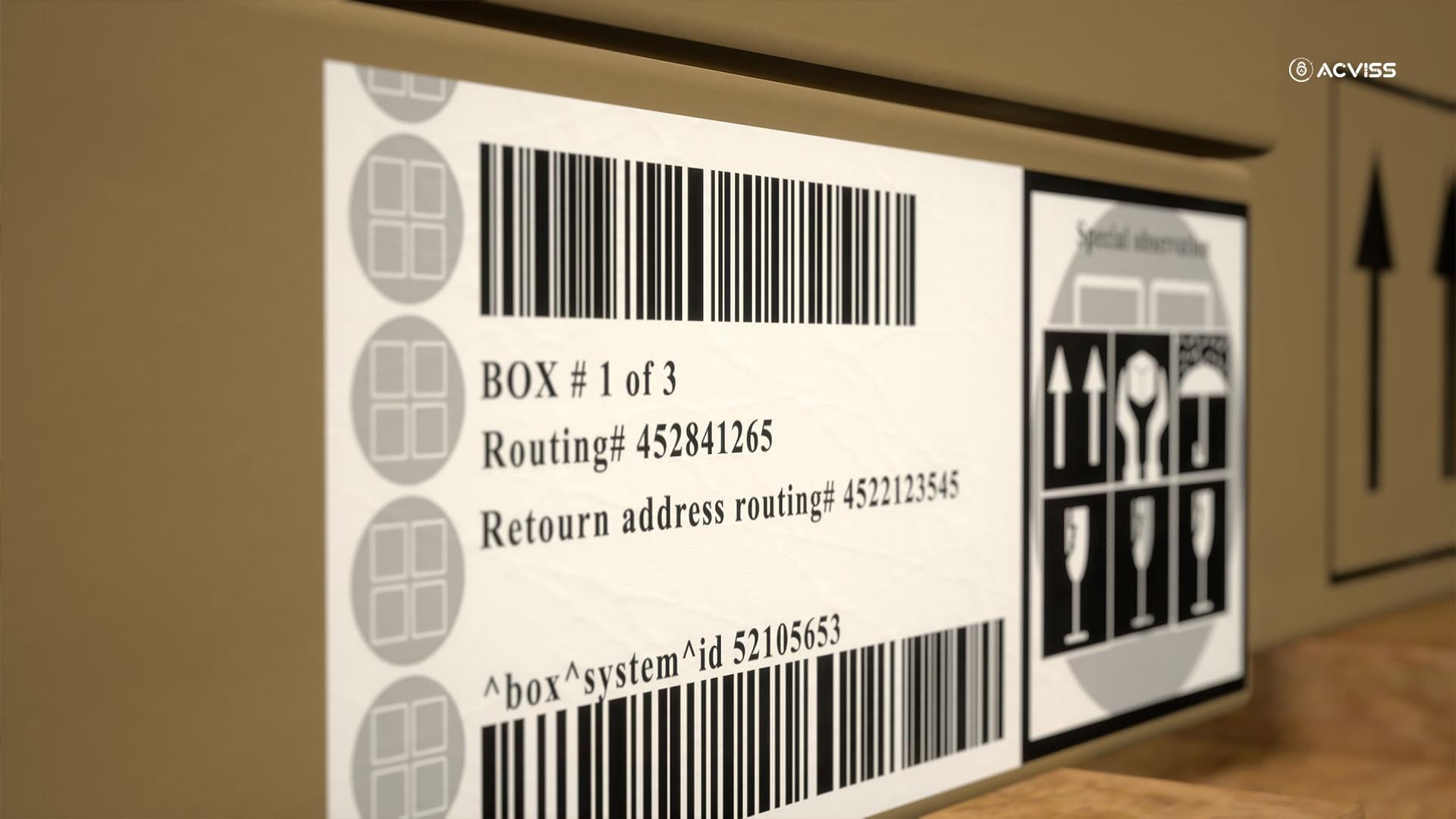

2. Serialisation and Unique Identification Codes

Every auto part can be embedded with serialised barcodes, QR codes, or RFID tags to allow real-time authentication.

How It Works:

- Each component is given a non-replicable, unique identifier.

- Scanning the code provides instant details on the part’s manufacturer, origin, and supply chain journey.

- Manufacturers and repair shops can verify authenticity before installation.

To strengthen security, some companies integrate dynamic QR codes that change after every scan, preventing duplication. DNA markers and nano-labels are emerging as next-generation identifiers that offer forensic-level authentication.

3. Artificial Intelligence (AI) & Machine Learning (ML)

AI and ML-powered systems can analyse supply chain data to detect irregularities and predict counterfeit risks.

Applications of AI in Counterfeit Detection:

- Predictive Analytics: Identifies high-risk suppliers and weak points in the supply chain.

- Computer Vision: Scans and detects fake packaging, labels, and product features.

- Deep Learning Models: Cross-checks product details against global databases to detect inconsistencies.

AI is also playing a role in voice and text analysis, scanning customer reviews and complaints for patterns indicating counterfeit issues. Moreover, conversational AI chatbots are being deployed to guide consumers in verifying genuine parts.

4. Internet of Things (IoT): Real-Time Tracking and Monitoring

IoT-enabled smart sensors and tracking devices provide real-time data on the location, handling, and environmental conditions of auto parts.

How IoT Enhances Traceability:

- RFID & NFC Tags: Enable seamless tracking at every checkpoint.

- Geo-Fencing: Alerts manufacturers when parts are moved outside designated supply routes.

- Condition Monitoring: Detects exposure to extreme temperatures or tampering attempts.

IoT solutions automate data collection and verification, reducing reliance on manual inspections and ensuring only authentic, high-quality parts reach assembly lines. This is especially critical for safety components like airbags and brake systems, where defects or counterfeit parts can have catastrophic consequences. IoT ensures regulatory compliance through real-time audit trails, while its integration with AI and blockchain strengthens supply chain security and trust.

Challenges in Implementing Traceability Solutions

Despite the benefits, enhancing supply chain traceability comes with challenges:

- Integration Complexity: Many companies still rely on outdated systems that struggle to integrate with modern traceability solutions.

- High Implementation Costs: Blockchain, AI, and IoT require significant investment, making adoption difficult for smaller suppliers.

- Data Privacy Concerns: Sharing supply chain data across multiple stakeholders raises security issues.

- Resistance from Suppliers: Some suppliers fear increased scrutiny and compliance burdens.

Best Practices for Strengthening Supply Chain Traceability

1. Industry-Wide Collaboration

- Automakers, suppliers, and regulators must establish unified traceability standards.

- Partnerships with anti-counterfeiting solution providers can enhance verification mechanisms.

2. Adoption of Global Standards

- Following GS1, ISO 16678 (authentication protocols), and SAE J2725 (auto part identification) ensures standardised tracking across the industry.

- Compliance with regulations like the U.S. Automotive Parts Traceability Act reinforces market credibility.

3. Consumer Awareness and Education

- Educating buyers on verifying genuine parts using QR codes or digital authentication tools.

- Promoting the use of authorised service centres over independent repair shops that may unknowingly use counterfeit components.

Acviss: Strengthening Supply Chain Security with Certify

As counterfeit auto parts continue to infiltrate supply chains, Acviss provides cutting-edge anti-counterfeiting solutions to help manufacturers safeguard their products. One of its key innovations, Certify, is a AI integrated product authentication system that combines non-cloneable security code for instant verification of auto parts, ensuring only genuine components reach consumers.

How Certify Enhances Traceability:

- Unique, Tamper-Proof Digital Codes: Each part is assigned a secure, non-replicable identity for easy authentication.

- Real-Time Analytics and Tracking: Allows manufacturers to monitor product movement, detect irregularities, and respond swiftly to supply chain threats.

- Seamless Integration with Blockchain, AI, and IoT: Strengthens overall traceability by adding multiple layers of security.

- Regulatory Compliance Support: Helps automakers meet industry standards such as ISO 9001, IATF 16949, and UNECE R90, reducing the risk of non-compliance penalties.

Implementing Certify enables automakers to 1 into their supply chains, making it easier to identify counterfeit threats, track genuine parts, and improve recall efficiency. The solution ensures that substandard components are kept out of the market and enhances consumer trust by offering transparent, verifiable authentication at every stage of the product lifecycle. As the automotive industry shifts towards digital-first security and traceability, Certify plays a crucial role in helping brands maintain integrity, protect revenues, and comply with evolving regulations.

The Road Ahead: A Future of Secure Auto Supply Chains

As counterfeit auto parts continue to endanger road safety and erode brand trust, enhancing supply chain traceability is non-negotiable. Advanced technologies like blockchain, AI, IoT, and serialisation provide a robust framework to track, verify, and eliminate counterfeits at every stage of the supply chain.

Investing in cutting-edge traceability solutions today will protect consumers, strengthen regulatory compliance, and future-proof the automotive industry against counterfeit threats.

What’s Next?

If you’re an automotive manufacturer or supplier, now is the time to embrace next-generation traceability solutions to safeguard your brand and enhance supply chain security. Get in touch with us today and secure your brand in the global market.