From Holograms to Non Cloneable Codes: When to Upgrade Your Security

Why Many Brands Are Rethinking Holograms

For decades, holograms have been the default choice for product security. They are visible, familiar, and easy to explain to distributors and customers. However, the threat landscape has changed.

Today’s counterfeiters are technologically capable, well-funded, and fast-moving. What once acted as a strong deterrent has become a visual formality.

Manufacturers across FMCG, pharmaceuticals, agro inputs, electronics, automotive parts, and lifestyle goods are now asking a critical question.

When is it time to move beyond holograms?

This blog explains the upgrade path, not as a sudden replacement, but as a strategic evolution toward non-cloneable security.

What Holograms Were Designed to Solve

Holograms were originally introduced to solve three problems:

Provide a visible security feature that is hard to replicate

Help inspectors and distributors visually identify genuine products

Act as a deterrent against casual counterfeiters

For a long time, this worked.

Replication required specialised equipment, and most counterfeit operations stayed away.

That is no longer the case.

Why Holograms Are No Longer Enough

Modern counterfeiters can replicate holograms at scale.

Advances in printing, scanning, and material access have reduced the cost and complexity of duplication.

Common issues manufacturers face today include:

Holograms that look identical on genuine and fake products

No way to verify authenticity digitally

Zero traceability once the product leaves the factory

Distributors are unable to distinguish originals from high-quality copies

Consumers are relying on guesswork instead of verification

In short, holograms are static. Static security fails in dynamic markets.

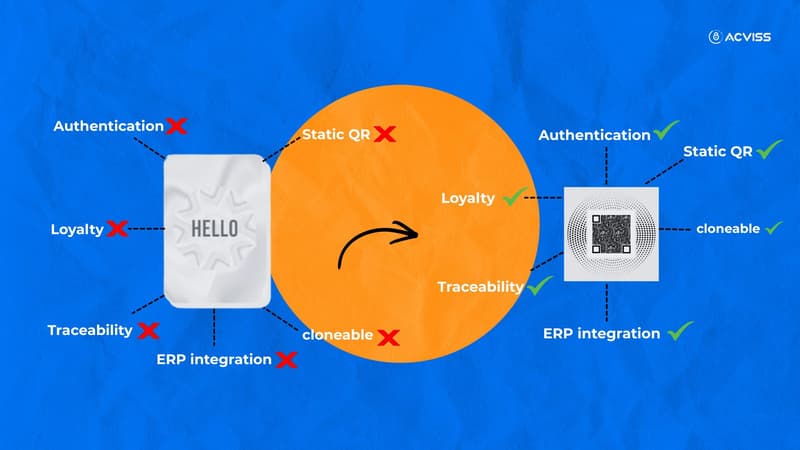

Understanding the Difference: Hologram vs Secure QR

When manufacturers evaluate holograms vs. secure QR codes, the real difference lies in how security behaves in the field.

A hologram is a passive indicator.

A secure QR code is an active verification mechanism.

Key differences include:

A hologram can be copied visually, while a secure QR can be validated digitally

A hologram does not change after application, while a QR scan generates live data

A hologram cannot detect duplication, while secure systems flag repeated or suspicious scans

A hologram provides no analytics, while QR-based systems generate intelligence

This does not mean QR alone is enough.

The real upgrade happens when QR codes are paired with non-clonable labels.

What Makes a Label Truly Non-Cloneable

Not all QR-based solutions are secure.

Standard QR codes can be copied, shared, or redirected.

Non-cloneable labels solve this problem by embedding physical uniqueness into each label.

Characteristics of non-cloneable labels include:

Physically random patterns that cannot be reproduced

One-to-one mapping between the physical label and its digital identity

Authentication that validates the physical structure, not just the printed code

Automatic detection of copied or reused identities

This means even if a counterfeiter copies the visual appearance, the system detects it immediately.

When Manufacturers Should Upgrade From Holograms

The decision to upgrade should be based on risk, scale, and business impact.

You should seriously evaluate an upgrade if:

Your products are being counterfeited despite hologram usage

Distributors report look-alike or duplicate labels in the market

You sell high-value or safety-critical products

You operate across multiple regions or channels

You sell on e-commerce marketplaces

You need data on where and how counterfeits appear

If security is still purely visual, the upgrade is overdue.

The Upgrade Path Does Not Have to Be Disruptive

A common misconception is that moving away from holograms requires a complete packaging overhaul.

In reality, many manufacturers adopt a phased approach:

Introduce non-cloneable labels alongside existing holograms

Enable QR-based authentication for distributors and field teams

Gradually educate consumers on scanning and verification

Use scan data to identify risk regions and channels

Phase out holograms once digital verification becomes standard

This reduces risk, minimises operational disruption, and allows teams to adapt smoothly.

Why Uniqolabel Is Designed for This Transition

Uniqolabel is built specifically for manufacturers moving beyond static security.

It combines:

Non-cloneable physical labels that cannot be copied

Secure QR-based authentication for real-time verification

Duplicate and anomaly detection

Integration with traceability and analytics platforms

Compatibility with existing packaging and workflows

Instead of relying on appearance, Uniqolabel shifts security to verification.

This changes the role of security from a passive deterrent to an active control system.

Business Benefits Beyond Counterfeit Prevention

Upgrading security delivers benefits beyond stopping fakes.

Manufacturers gain:

Visibility into product movement and scan locations

Early warning signals for diversion and parallel trade

Cleaner distributor and retailer accountability

Higher consumer trust at the point of purchase

Data-driven decisions instead of assumptions

Security becomes a source of intelligence, not just protection.

A Practical Evaluation Checklist

When comparing anti-counterfeit tech vendors, ask:

Is the label physically non-cloneable

Can the system detect copied identities in real time

Does authentication work in low-connectivity environments

Can the solution scale to millions of units

Does it integrate with ERP or traceability platforms

Who owns the data generated by scans

If the answer is unclear, the solution is not future-ready.

The New Standard in Product Security

Holograms had their time.

They solved yesterday’s problems.

Today’s environment requires security that can respond, adapt, and provide proof.

Non-cloneable labels and secure QR-based authentication represent the new standard.

Manufacturers who upgrade early protect not only their products but also their brand equity and channel relationships.

And for brands that are buying holograms,

If your security strategy still depends on holograms alone, it is time to reassess.

Uniqolabel helps manufacturers transition from static visual security to non-cloneable, digitally verifiable protection that scales across markets and channels.

Explore how Uniqolabel can upgrade your anti-counterfeit strategy without disrupting your operations.