Smart Packaging for FMCG: Solving Diversion with Parent-Child Coding

When you buy a shampoo bottle in Delhi that was meant for distribution in Patna, there’s more than just a logistics error at play. You’re staring at a costly, silent problem in the fast-moving consumer goods (FMCG) industry: product diversion.

It’s the kind of challenge that grows with your brand, eats into margins, disrupts your retail strategy, and makes your regional market teams jittery. But more than that, diversion erodes brand trust and complicates supply chain management, especially when left unchecked across large, fragmented geographies.

Let’s unpack how this clever technology, when paired with robust track and trace systems and product authentication tools, offers a game-changing response to one of FMCG’s most persistent threats.

The Underestimated Menace of Product Diversion

Product diversion isn’t just a grey market problem. It’s a strategic nightmare. A shampoo bottle, tube of toothpaste, or baby formula packet manufactured for one region ends up being sold in another through unauthorised channels, often at a lower price or in violation of specific regulatory conditions.

Why is this so damaging?

- Disrupts region-wise pricing strategies

- Harms channel partner relationships

- Complicates taxation and compliance audits

- Dilutes brand positioning across markets

- Makes genuine stock appear ‘fake’ or irregular

For growing FMCG brands expanding across Tier 2 and Tier 3 cities, especially in countries like India, managing the movement of goods without misrouting, tampering, or mislabeling has become a priority.

Smart Packaging: The First Line of Defence

Smart packaging is no longer a buzzword for "futuristic" brands. It’s a functional necessity in modern-day brand protection strategies.

But what do we mean by “smart”?

Smart packaging refers to packaging that’s enhanced with digital features, QR codes, NFC chips, data matrices, or non-cloneable identifiers, that make the packaging interactive, traceable, and verifiable throughout the product lifecycle.

It turns passive packaging into an active source of truth.

And in solving diversion, one specific innovation within smart packaging stands tall: Parent-Child Coding.

Understanding Parent-Child Coding: Simple in Concept, Powerful in Impact

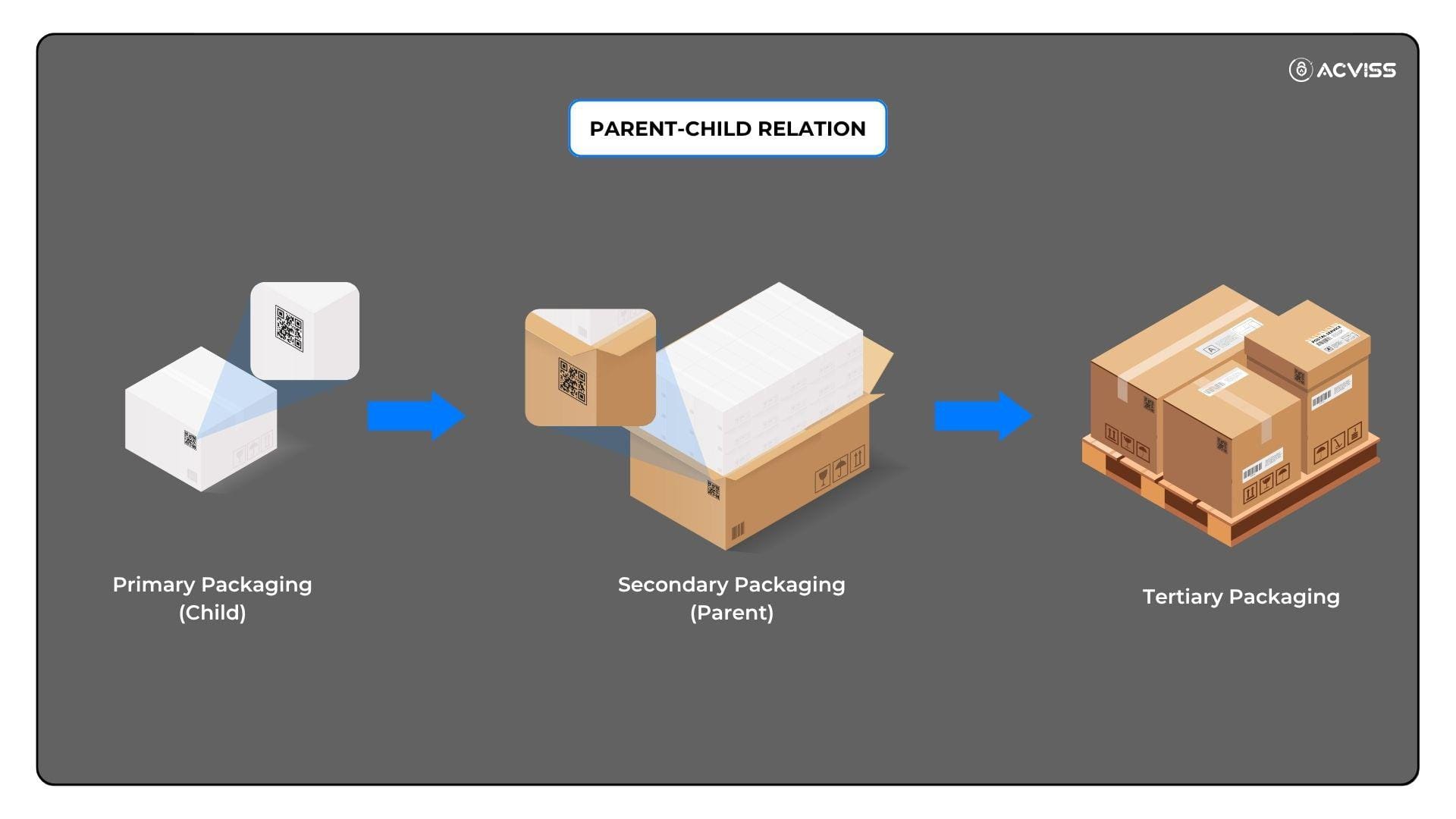

Parent-Child Coding is a hierarchical serialisation method that creates a relationship between individual product units (child codes) and their larger shipping or packaging units (parent codes).

Here’s how it works:

- Each product unit (e.g., a bottle or sachet) receives a unique “child” code.

- These units are grouped into cartons, which are assigned a “parent” code.

- Further grouping (e.g., pallets or consignments) leads to the generation of grandparent codes.

- All codes are linked in a digital database, forming a traceable, interlocked tree of product movement.

This allows brands to monitor the journey of every unit, understand exactly which batch it came from, and detect any discrepancy in distribution paths.

For example:

If a product with Parent Code X is meant for Gujarat but shows up in Kerala, the system immediately flags the breach.

Why Parent-Child Coding is Tailored for FMCG Brands

FMCG supply chains are characterised by volume, speed, and scale. Implementing a traditional anti-diversion strategy, like physical audits or channel checks, is not only costly but also impractical at scale.

Here’s what makes parent-child coding ideal:

1. Granular Product Traceability

Every unit is accounted for, from manufacturing to the retail shelf. This drastically increases supply chain transparency and helps in product verification at every node.

2. Automated Diversion Alerts

Real-time systems can track when a product surfaces in the wrong market, enabling timely investigations and course corrections.

3. Simplified Recall & Compliance

If a specific batch is found faulty, parent-child mapping allows brands to trace and recall only the affected units, not entire shipments.

4. Layered Brand Protection

By pairing this coding system with tamper-evident seals, non-cloneable labels, and authentication technologies, it becomes exponentially harder for counterfeiters or grey market operatives to mimic products.

Where Anti-Counterfeiting Technologies Fit In

Diversion and counterfeiting are often two sides of the same coin. A product that’s been diverted can easily be passed off as authentic, even if tampered with. That’s why product authentication and brand verification must work alongside diversion control.

Leading solutions today integrate:

- IP protection tools that verify product originality

- Trademark protection via registered digital identities

- Consumer-facing verification systems via QR or NFC scans

- AI-driven analytics that flag suspicious market activity

These brand protection solutions not only reduce counterfeits but also help strengthen brand integrity in the eyes of distributors, retailers, and consumers.

Why Diversion Demands Proactive Technology, Not Just Policy

Brands often treat diversion as a compliance or logistics problem. But the reality is, it’s a technology problem with a technological solution.

Manual SOPs, NDAs, and distributor agreements are rarely enough. What’s needed is:

- Automated product authentication across the value chain

- Systematic product traceability using real-time data

- End-to-end visibility into product lifecycle, not just dispatches

- Digital IP protection to prevent unauthorised access or replication of brand identifiers

Simply put: Technology provides the enforcement muscle that policy alone cannot.

The Human Side of Diversion: Trust at Stake

Imagine the field sales executive trying to explain to a retailer why they should buy at MRP when diverted stock is available for less. Or a regional manager explaining poor sales performance due to undercutting by unauthorised distributors.

Diversion doesn’t just hit margins. It fragments your sales culture, creates internal distrust, and affects the credibility of your brand's presence in regional markets.

Solving this starts by giving your teams and your consumers a way to trust the product journey.

Modern Brand Authentication in Action

Forward-looking brands have started embedding non-cloneable QR codes or digital identity tags on each unit. These tags enable:

- Customer-level product verification

- Retailer validation before stocking

- Instant backend alerts when codes are scanned out of zone

For example, a verified anti-counterfeiting solution can alert a brand when a product meant for Uttar Pradesh is scanned by a customer in Tamil Nadu, a potential red flag indicating diversion or parallel imports.

The result? Brands are no longer in the dark.

Integrating with Your Supply Chain: The Role of Digital Track and Trace

While parent-child coding forms the backbone, its true power lies in integration with a track and trace system. This is where enterprise-wide transparency emerges, when the data from manufacturing, warehousing, distribution, and retail flows into a single dashboard.

Solutions like Acviss’s product authentication and traceability systems bring this together. With technologies that combine digital serialisation, real-time verification, and AI analytics, brands can transition from reactive problem-solving to proactive threat detection.

From Smart Packaging to Smarter Brands

In a market that’s only getting more competitive, controlling diversion is no longer optional; it’s essential to brand survival.

And for those looking to take this one step further, beyond codes and control, solutions like Origin by Acviss provide blockchain-enabled track and trace across the entire supply chain. This means tamper-proof, end-to-end visibility into not just where your products are, but where they’re meant to be.

Interested in building a traceable, verifiable product experience? Let Acviss help you create a future where every product tells its own story, genuinely. Learn more about our product authentication and traceability solutions from our experts!