Label Printing Systems: How They Work and Why They Matter for Manufacturers

In today's complex supply chains, printing the right label is no longer only about branding. It plays a critical role in ensuring trust, traceability, and regulatory compliance. Whether you're in pharma, agrochemicals, FMCG, or auto parts, a label printing system is the backbone of your product identity.

What Is a Label Printing System?

A label printing system is a setup that combines hardware and software to generate and print product labels, often including:

- Barcodes

- QR codes

- Batch numbers

- Expiry and manufacturing dates

- Brand or compliance information

These labels act as gateways to authentication and tracking, allowing regulators, brands, and customers to verify product legitimacy.

Core Components of a Label Printing System

1. Code Generation Engine

Integrated with platforms like Acviss Origin, this engine generates:

- Unique serial numbers

- QR codes (including non-cloneable ones)

- GS1 standard barcodes

Ensures unit-level uniqueness.

2. Label Design Software

Tools like BarTender or NiceLabel allow:

- Logo placement

- Custom layout of product details

- Variable QR/barcode insertion

This enables real-time personalization.

3. Industrial Printer Hardware

Devices like Zebra, TSC, and Sato print high-resolution labels.

- Thermal transfer or direct thermal

- Connected via API, USB, or LAN This supports high-speed packaging lines.

4. Label Materials

Choose depending on industry:

- Tamper-proof

- Waterproof

- Holographic labels

This strengthens product protection.

5. Real-Time Verification System (Optional)

- OCR scanners or image recognition cameras verify print accuracy This helps prevent labelling errors and regulatory issues.

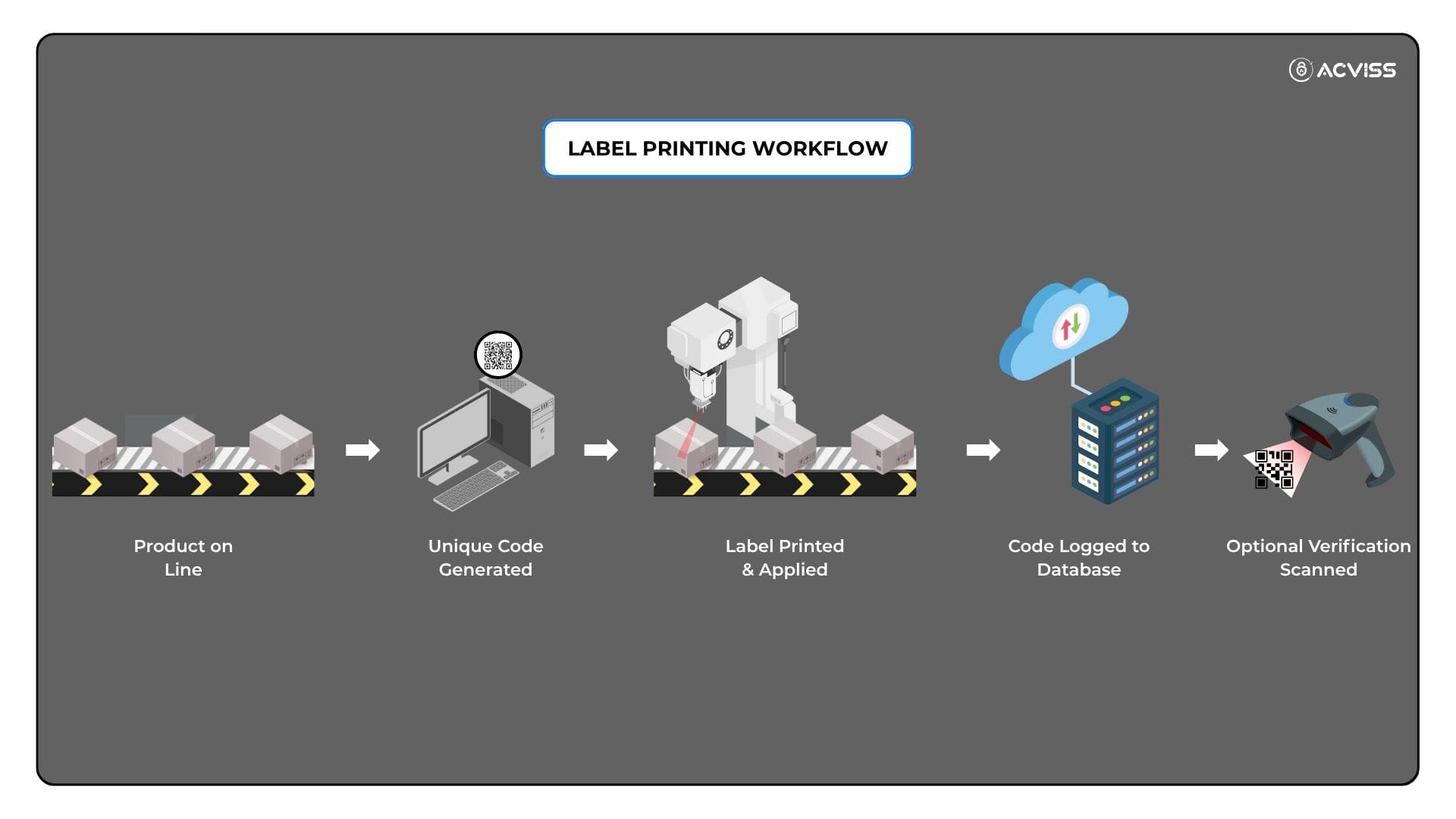

How a Label Printing Workflow Typically Operates

A typical label printing workflow ensures efficient product identification and tracking. Here’s how it works:

Product on Line: The process begins as products move through the production line.

Unique Code Generated: Each item is assigned a distinct identifier (e.g., barcode or QR code).

Label Printed & Applied: The code is printed on a label and attached to the product.

Code Logged to Database: The identifier is recorded in a system for tracking and management.

Optional Verification Scan: A final scan may confirm accuracy before shipping.

This seamless workflow enhances traceability, reduces errors, and supports inventory or quality control.

Want to optimize your labelling process? Explore advanced solutions today!

Industry-Specific Use Cases

Auto Parts

- Track warranty and parts authenticity

Ensure only genuine parts reach mechanics and service centers, especially in India's booming aftermarket segment. - Prevent after-market counterfeit components

Auto brands globally use serialized labels to identify and flag unauthenticated parts before they enter the supply chain. - Enable real-time scan-based service logs

Mechanics can scan parts for history and compatibility, reducing misfit or duplication.

Pharmaceuticals

- Comply with DSCSA, FMD

Serialization is now mandatory under US and EU regulations; India’s iVEDA rollout also mandates traceability at primary and secondary levels. - Recall tracing and validation

Unique codes help identify affected batches instantly, ensuring safer and quicker product recalls. - Counterfeit deterrence at chemist level

QR verification empowers pharmacists and consumers to validate medicines at the point of sale.

FMCG

- Unit-level scan for customer engagement

Brands can drive digital interaction with QR-led contests, AR experiences, or scan-to-win programs. - Promotions or loyalty programs

Each product becomes a channel to connect with consumers, encouraging repeat purchases. - Monitor scan patterns by region

Brands can detect market-level fake product trends through QR scan analytics.

You can also read Smart Packaging for FMCG with Parent-Child Coding

Agrochemicals

- Mandated QR codes for licensing

India’s CIBRC guidelines make QR-based traceability essential for agrochemical manufacturers. - Authentication for regulated distribution

Labels help ensure only certified dealers handle products, avoiding diversion or black marketing. - Farmer verification and feedback integration

Brands can link QR scans to farmer education content, boosting loyalty and correct usage.

How Acviss Enhances Label Printing with Origin

- Parent-child traceability: Map unit, box, and pallet labels

- Non-cloneable QR codes: Built-in anti-counterfeit protection

- Geo + OTP scan validation: Ensures only legitimate scans

- Track scan history by user, location, and time

Use Origin’s dashboard to link each printed label with a verified product ID in real-time.

Benefits of a Label Printing System

Feature | Benefit |

|---|---|

Serialization | Unique identity for every product |

QR/Barcode printing | Easy scan and verify anywhere |

ERP/API integration | Real-time data sync |

Secure labelling | Prevent counterfeits at packaging level |

Schedule a Demo

Want to secure your supply chain and automate serialization?

Book a personalized demo with Acviss.

Conclusion

A modern label printing system is more than just a printer. It acts as the initial checkpoint in your product’s trust journey, ensuring visibility, compliance, and authenticity right from the start of the production line. When combined with a platform like Acviss Origin, it becomes your frontline defence against counterfeiting and supply chain ambiguity.