Why Inventory Visibility Stops at the Warehouse and How Traceability Extends It

Most brands proudly claim to have “complete inventory visibility.”

But the truth is, visibility often ends the moment goods leave the warehouse.

Across industries such as agro-chemicals, paints, pharmaceuticals, and FMCG, supply chains are rarely linear. They weave through distributors, sub-dealers, retailers, and sometimes field representatives before finally reaching consumers. Each handoff adds complexity — and every added layer increases the chance of losing sight of where products actually are.

Once goods leave the factory or warehouse, brands rely heavily on manual reports, periodic ERP updates, or third-party data to estimate where their inventory might be. This creates a dangerous gap, a blind spot where visibility stops and risk begins.

This gap can conceal critical issues such as stock leakages, parallel trade, product diversions, and even counterfeit replacements. What looks like smooth logistics on paper may actually be a network filled with opacity and loss. The outcome? Shrinking profits, compromised brand integrity, and an erosion of consumer trust.

A 2024 McKinsey report revealed that 60% of brands cannot accurately trace their products beyond the first distribution tier, and over 40% of returns or damaged goods go unrecorded in central systems. These are not just numbers; they represent a systemic lack of control that affects every layer of brand protection.

The Problem: Visibility Ends Where Risk Begins

Warehouses today are digital marvels. They use barcode scanners, RFID systems, integrated ERP software, and real-time stock dashboards. Inside the warehouse, every item is accounted for. But once a product crosses the dispatch gate, that precision fades.

Here’s where things begin to go wrong:

Distributors reassign shipments to sub-dealers or other channels without brand oversight.

Retailers manage unsynchronised stock, which doesn’t always reflect in central inventory systems.

Counterfeit or refilled products enter the chain unnoticed, often disguised under genuine product identifiers.

Returns or replacements are handled locally, creating mismatches between physical and digital records.

This fragmented chain of custody means brands cannot confidently answer simple yet crucial questions such as:

“Where exactly is this batch right now?”

“Has this product reached its intended market?”

“Are fake or diverted products circulating under our name?”

When inventory visibility stops at the warehouse, brands lose control over the very assets that define their reputation. It’s like navigating with a GPS that stops working halfway through the journey

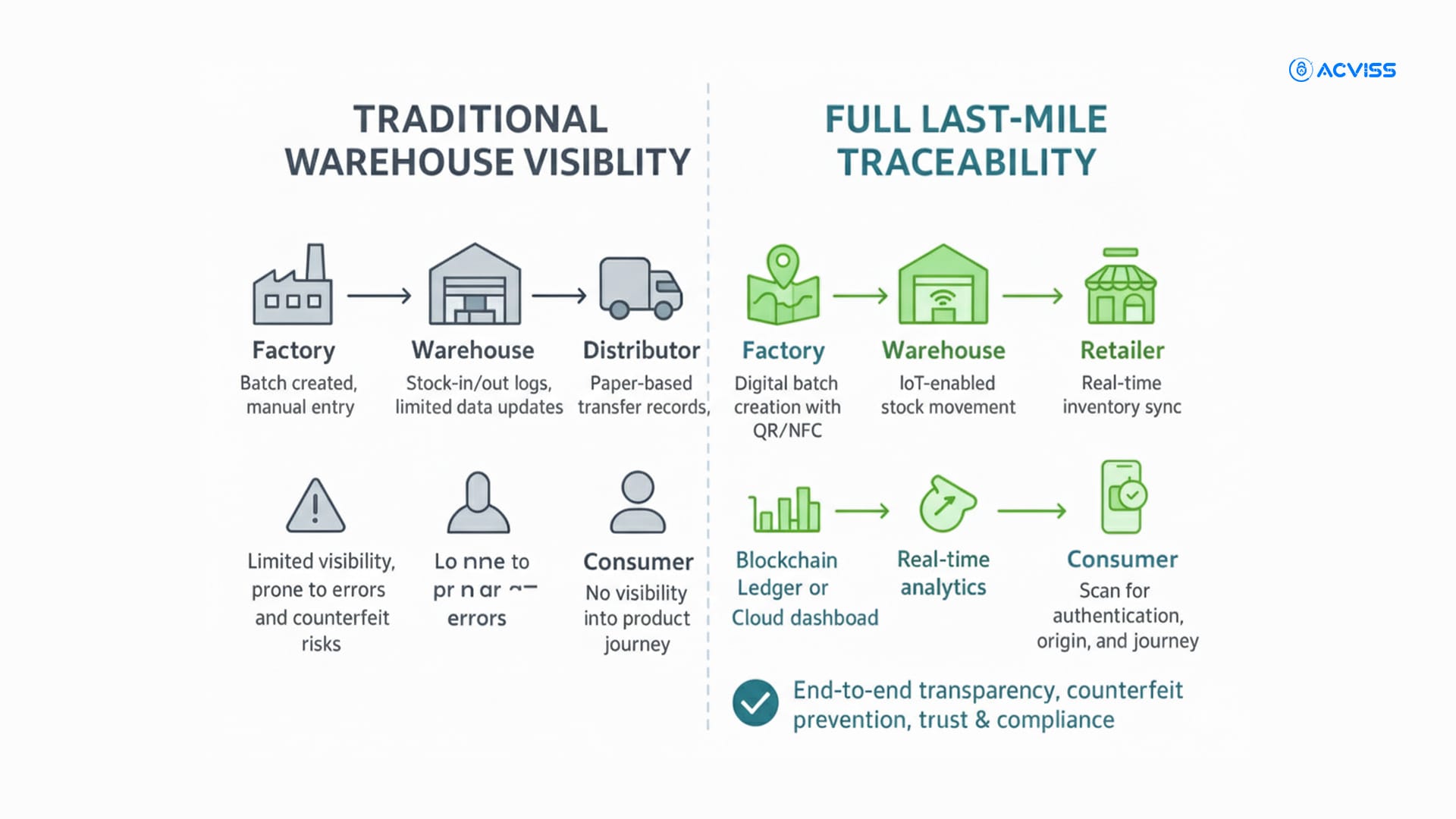

Why Traditional Systems Aren’t Enough

The limitations lie in how traditional supply chain management systems are structured. ERP and WMS platforms primarily record what happens within controlled environments, production, storage, and dispatch. They are excellent for internal visibility but lack the real-time responsiveness needed once goods move externally.

Even barcodes, which have been the backbone of tracking for decades, cannot provide the granular, unit-level product traceability required to monitor items individually. A barcode identifies a batch, not a unique unit. This opens doors to grey market activity, counterfeit infiltration, and parallel distribution.

As markets expand and digital commerce grows, the ability to know what happens after dispatch has become as critical as what happens before it.

This is where traceability technologies take the spotlight, offering visibility that doesn’t just end at the warehouse gate, but extends all the way to the consumer’s hand.

The Solution: Extending Visibility with Serialised Traceability

To bridge this gap, forward-thinking brands are adopting serialised traceability systems that assign every single unit a unique digital identity.

This is where Acviss Origin, a QR-based traceability platform, redefines visibility for modern supply chains.

Unlike traditional batch tracking, Origin tracks each individual pack, assigning it a unique, non-cloneable QR identity that stays with the product throughout its lifecycle. It’s a digital fingerprint that cannot be duplicated, replicated, or tampered with, ensuring authenticity at every point of contact.

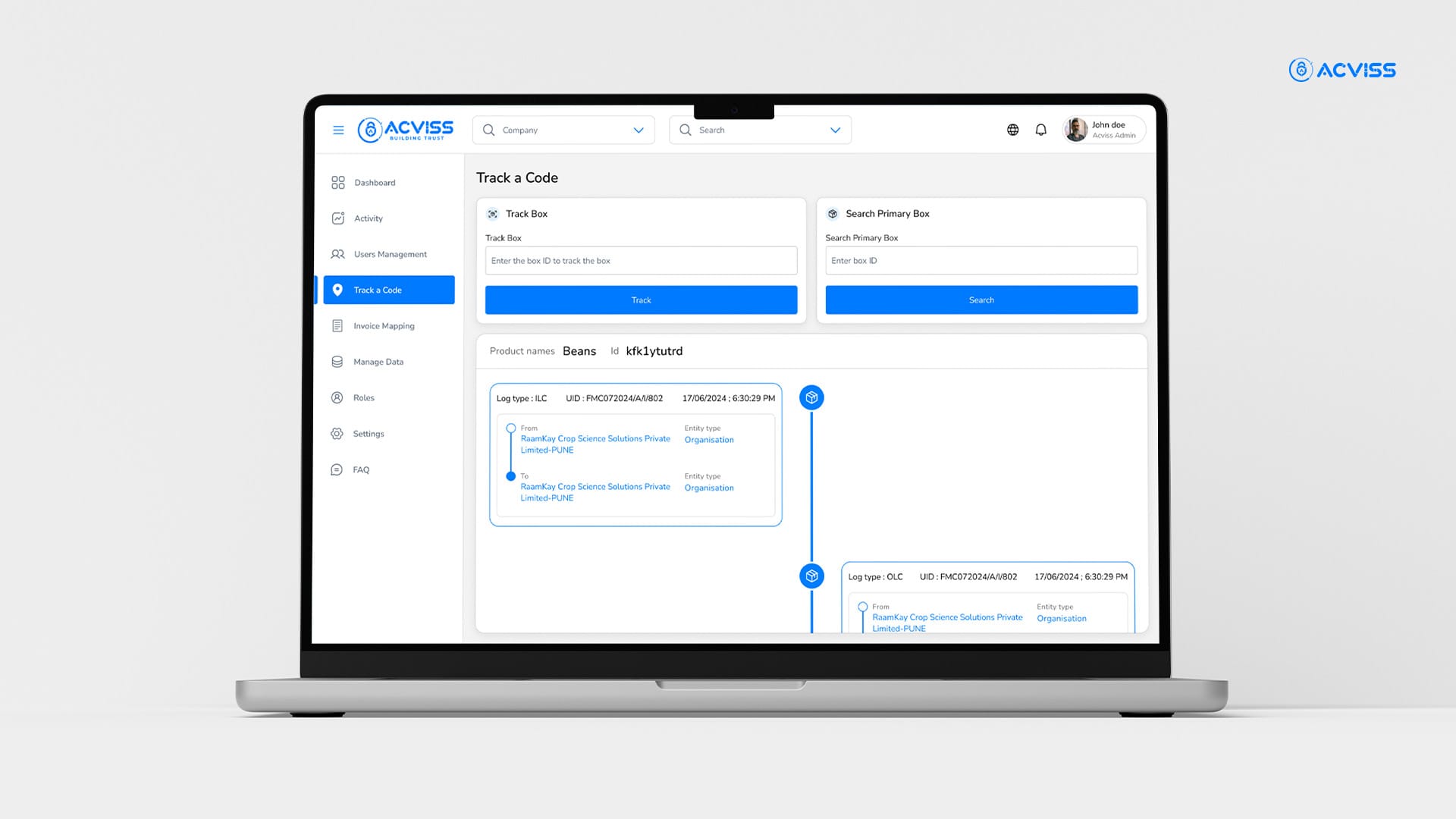

How It Works

1. Serialisation at the Source

Every product unit is embedded with a unique QR code or digital ID at the production stage. These codes are cryptographically secured and non-replicable, ensuring fool-proof authentication.

2. Tracking Every Hand-off

As products move through the supply chain, from warehouse to distributor, retailer, and finally to the end consumer, each scan automatically updates a centralised traceability system. This builds a live, digital trail of every movement.

3. Real-Time Insights

With every scan, Origin’s dashboard offers live analytics, displaying product locations, batch movements, and irregularities. Brands can immediately detect if a shipment is stagnant, diverted, or potentially compromised.

4. Verification at Retail or Consumer End

Consumers can scan the same QR to verify authenticity, adding another layer of data and engagement. This creates a closed-loop system where the end-user becomes part of the traceability process.

In essence, traceability transforms static inventory data into a living, breathing digital twin of your supply chain, one that evolves with every movement and interaction.

How Last-Mile Traceability Protects Brands

When traceability extends beyond the warehouse, visibility transforms into brand protection, operational intelligence, and consumer trust.

Let’s explore how:

1. Eliminates Distribution Blackouts

Every scan, whether by a distributor, retailer, or field agent, updates the product’s digital journey. Brands can pinpoint where stock is sitting idle, detect unauthorised reselling, or identify regional sales imbalances. This visibility enables proactive supply chain management rather than reactive problem-solving.

2. Prevents Counterfeiting and Diversion

Counterfeit infiltration thrives in opacity. With non-cloneable digital identifiers, fake products cannot mimic genuine ones. If duplicate or unauthorised codes appear in the system, they are flagged instantly.

This technology forms the backbone of anti-counterfeiting solutions, reinforcing IP protection, brand verification, and product authentication.

3. Enables Data-Driven Demand Planning

With real-time sales and movement data, brands no longer have to depend solely on delayed distributor reports. The insights gathered from field-level traceability improve forecasting accuracy and inventory replenishment, ensuring better alignment with market demand.

4. Strengthens Consumer Trust

Consumers increasingly demand transparency. When they can verify product authenticity themselves, it builds brand confidence and enhances customer engagement. Every scan also contributes valuable feedback, where, when, and how customers interact with your products.

A 2023 Deloitte study noted that brands with traceability systems in place saw up to a 20% increase in consumer satisfaction, as customers valued the visible commitment to safety and authenticity.

Industry Use Cases: Visibility Beyond Dispatch

1. Agro-Chemicals

Counterfeit pesticides are a major threat in rural markets. Fake formulations not only harm crops but also risk farmer safety. With Origin’s unit-level traceability, brands can track every bottle, ensuring only genuine products reach farmers. Distributors and retailers can verify authenticity before sale, reducing counterfeit infiltration.

2. Pharmaceuticals

Regulations increasingly demand end-to-end tracking of medical products. Origin helps pharmaceutical brands trace every batch post-dispatch, allowing instant recall management, regulatory compliance, and proof of authenticity. In markets where patient safety is paramount, product verification isn’t optional; it’s essential.

3. Paints & Adhesives

Overlapping distributor networks often lead to regional diversions and unrecorded substitutions. With traceability, brands can confirm that each can of paint or adhesive reaches its intended market. Unauthorised redistribution or stock manipulation becomes instantly visible.

4. FMCG

For fast-moving consumer goods, shelf-level visibility is a game-changer. Traceability helps monitor product freshness, expiry timelines, and customer purchase patterns. It can also integrate with reward or loyalty programmes, offering insights into buying behaviour and reinforcing customer satisfaction.

Benefits in Numbers

The results of serialised traceability go beyond theory. Brands that have implemented track and trace systems report measurable improvements:

35–50% reduction in distributor disputes

30% faster recall tracebacks

20% improvement in forecasting accuracy

Zero counterfeit leakage in verified distribution zones

These aren’t isolated figures; they represent a paradigm shift in how brands manage, protect, and profit from their supply chains.

Integrating with Existing Systems

A major concern for brands is whether advanced traceability systems can coexist with their current infrastructure. The answer is yes.

Acviss Origin integrates seamlessly with ERP and warehouse management systems like SAP, Oracle, or custom-built platforms through secure APIs.

This means you don’t have to overhaul your existing system; instead, Origin extends it. Data from your warehouse merges effortlessly with field data, giving all departments, operations, logistics, and sales a single source of truth for every product’s journey.

Integration also means traceability and brand protection become continuous, not isolated. When a product is scanned, every team involved gains live visibility, ensuring consistency and accuracy across the ecosystem.

Why It’s a Strategic Advantage

In a market where every brand claims supply chain visibility, the differentiator lies in how far that visibility extends.

When your traceability reaches the last retail mile, you gain more than control; you gain predictive intelligence, counterfeit protection, and consumer confidence.

The future of inventory visibility isn’t inside the warehouse.

It’s everywhere your product travels.

Get in touch with us today to see how Acviss's Origin extends traceability beyond your warehouse.

FAQs

Q1: How is traceability different from regular inventory tracking?

Traditional inventory tracking records stock movement up to dispatch. Traceability tracks each product through every hand-off till it reaches the end consumer.

Q2: Can this system work with my existing ERP?

Yes. Acviss Origin integrates with existing ERP or WMS systems through APIs, ensuring seamless data exchange.

Q3: What if my distributors don’t use scanners?

Even basic smartphones can scan and update QR data, so implementation is lightweight and scalable.

Q4: Does it help with counterfeit prevention?

Absolutely. Each product carries a unique non-cloneable digital ID that prevents duplication and verifies authenticity instantly.