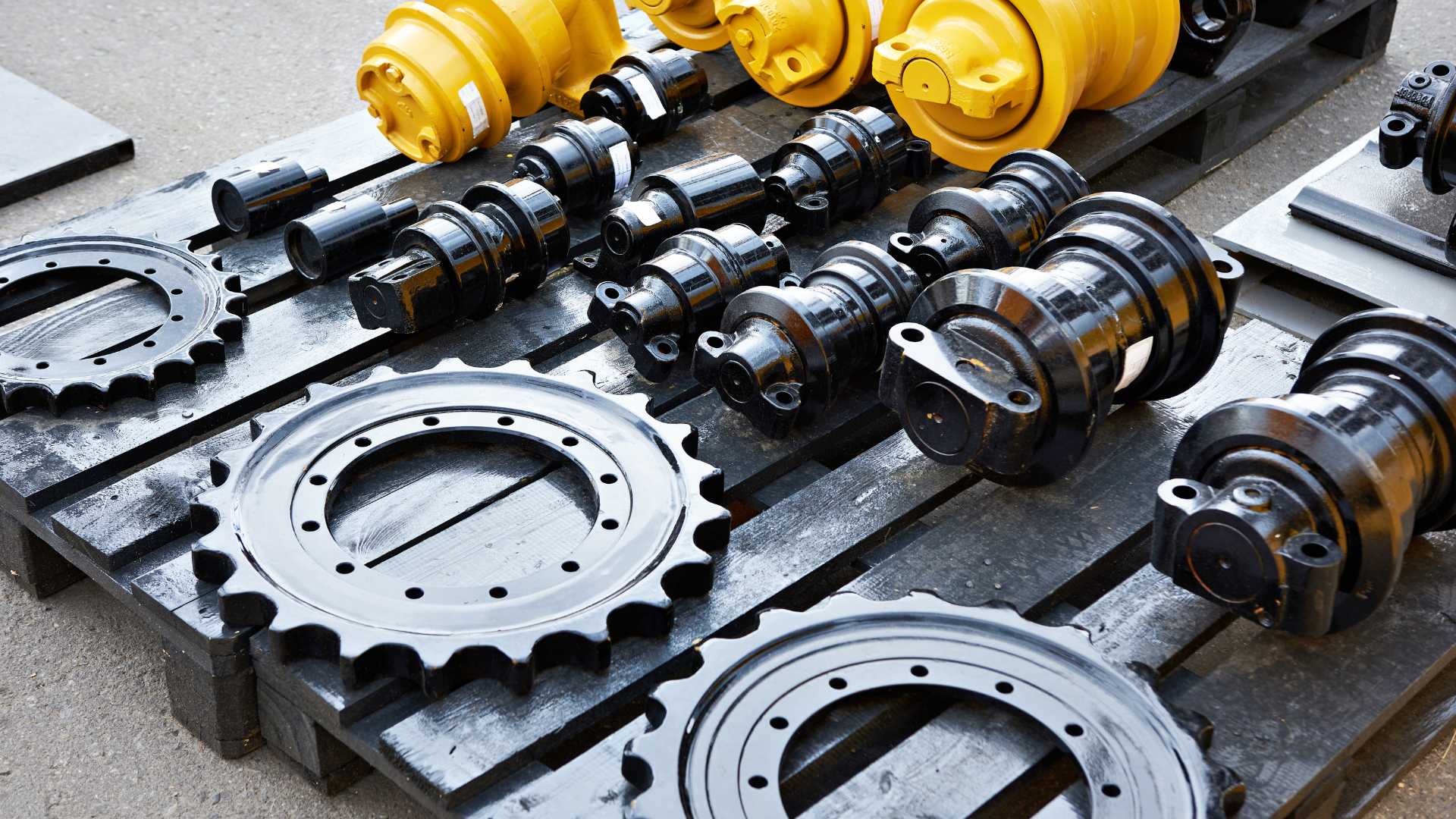

OEM vs Aftermarket Parts: Ensuring Authenticity and Quality

However, with counterfeit parts infiltrating global supply chains, ensuring authenticity and quality has become a major challenge. This article explores the key differences between OEM and aftermarket parts, the risks associated with counterfeit components, and the advanced methods being used to verify authenticity.

What are OEM Parts?

OEM parts are produced by the same manufacturer that supplied the original component of a product. These parts are made to match exact design specifications, ensuring a seamless fit and optimal performance. One of the most significant advantages of OEM parts is their consistency in quality, as they undergo rigorous testing and quality control before being released to the market.

A key benefit of OEM parts is that they come with a manufacturer’s warranty, offering assurance that they will function as intended. Since they are sourced directly from the manufacturer or authorised dealers, the risk of receiving counterfeit or low-quality parts is significantly reduced. However, this assurance comes at a price, as OEM parts tend to be more expensive than their aftermarket counterparts. Availability can sometimes be a challenge, as OEM parts are often sold exclusively through dealerships or specific distributors.

What are Aftermarket Parts?

Aftermarket parts are manufactured by third-party companies that design components either to replicate OEM specifications or to introduce modifications and enhancements. The quality of aftermarket parts varies widely, depending on the manufacturer’s reputation, materials used, and adherence to industry standards. Some aftermarket parts are engineered to exceed OEM performance by incorporating stronger materials or improved designs, making them a preferred choice in specific industries such as performance automotive upgrades.

One of the biggest advantages of aftermarket parts is their cost-effectiveness. These parts are generally more affordable than OEM components, making them an attractive option for consumers and businesses looking to save on maintenance and repairs. They are also widely available, as multiple manufacturers produce alternatives for the same component, offering greater flexibility in sourcing.

Key Differences Between OEM and Aftermarket Parts

Feature | OEM Parts | Aftermarket Parts |

|---|---|---|

Manufacturer | Produced by the original equipment manufacturer | Made by third-party manufacturers |

Quality Control | Stringent testing ensures consistency and reliability | Quality varies depending on the manufacturer |

Warranty | Comes with a manufacturer-backed warranty | Warranty coverage depends on the brand |

Fit & Compatibility | Designed to match the exact specifications of the original part | May require slight modifications for proper fit |

Availability | Limited to dealerships and authorised sellers | Easily available across various retailers |

Price | Generally higher due to brand assurance and quality control | More affordable, with the price depending on brand reputation |

Risk of Counterfeits | Lower risk due to controlled distribution | Higher risk, especially when purchased from unreliable sources |

The Rising Threat of Counterfeit Parts

Counterfeit parts have become a growing concern, particularly in industries where precision and safety are non-negotiable. The increasing reliance on online marketplaces and global supply chains has made it easier for fake components to infiltrate legitimate markets. These counterfeits often mimic the appearance of OEM or high-quality aftermarket parts but fail to meet industry standards for durability and performance.

Industries such as automotive, aerospace, medical equipment, electronics, and industrial machinery are among the most vulnerable to counterfeit parts. In the automotive sector, fakebrake pads, airbags, and fuel filters have been discovered, posing serious safety risks to drivers and passengers. In aerospace, the use of non-certified components in critical systems can lead to catastrophic failures. Similarly, counterfeit medical device parts can compromise patient safety, leading to incorrect readings, malfunctioning equipment, or even life-threatening situations.

The consequences of using counterfeit parts extend beyond performance issues. Businesses that unknowingly install counterfeit components risk violating industry regulations, facing legal consequences, and damaging their reputation. Fake parts tend to have shorter lifespans, leading to frequent replacements and increased long-term costs.

Quality Assurance Measures: How Manufacturers and Buyers Can Stay Protected

1. Authentication Technologies for OEM and Aftermarket Parts

With the rise in counterfeit parts, companies are turning to advanced authentication and traceability solutions. Some of the most effective technologies include:

a. Unique Serialisation & QR Code Verification

Manufacturers are increasingly using unique serial numbers and QR codes to help customers verify the authenticity of a product. Advanced non-cloneable codes can be scanned using a smartphone, directing the buyer to a secure database where they can confirm whether the part is genuine. This method is particularly effective for OEM parts, as manufacturers maintain a centralised record of all components produced.

b. Blockchain-Based Track and Trace

Blockchain technology is being used to create tamper-proof records of each part’s journey from manufacturing to the end user. Each transaction within the supply chain is recorded on a decentralised ledger, making it virtually impossible to alter or forge product history. This system enhances transparency and enables buyers to track the origin and movement of parts before purchase.

c. AI-Based Digital Scanning

Artificial intelligence is being deployed to identify counterfeit parts through image recognition and material analysis. AI-driven scanners can detect subtle differences in branding, engraving, and material composition that are often missed by the human eye. This technology is particularly useful for distinguishing between authentic and fake components in industries like automotive and electronics.

d. Tamper-Proof Labels and Holograms

Tamper-proof security features such as holograms, microtext printing, and UV-sensitive labels make it harder for counterfeiters to replicate OEM and high-quality aftermarket parts. These labels change appearance when viewed from different angles or under UV light, allowing consumers to verify authenticity instantly.

2. Choosing Reliable Aftermarket Parts: What to Look For

For those opting for aftermarket parts, it’s essential to distinguish between reputable brands and unreliable manufacturers. Here’s how buyers can assess quality:

Quality Indicator | OEM Parts | High-Quality Aftermarket Parts | Low-Quality Aftermarket Parts |

|---|---|---|---|

Material Quality | High-grade materials as per the manufacturer's specs | Often matches or slightly deviates | Uses inferior or substandard materials |

Certification & Testing | Meets the original manufacturer’s standards | Certified by third-party regulators | No certification or proof of quality |

Manufacturer Reputation | Established OEM brands | Trusted aftermarket brands with proven reliability | Unknown manufacturers, often from unverified sources |

Price | Expensive but ensures longevity | Mid-range pricing with good value | Extremely cheap but with compromised durability |

3. Best Practices for Buyers to Avoid Counterfeit Parts

For businesses and consumers looking to avoid fake components, adopting stringent verification methods is crucial. Key recommendations include:

- Purchase from Authorised Dealers: Always buy from certified OEM sellers or well-known aftermarket brands.

- Check Security Labels and QR Codes: Scan product packaging for traceability codes provided by the manufacturer.

- Inspect Packaging and Logos: Genuine OEM or quality aftermarket brands maintain consistent branding, while counterfeits often have slight inconsistencies.

- Request Certification or Compliance Reports: Genuine parts typically come with test reports or compliance documentation.

- Be Wary of Prices That Are Too Good to Be True: If an OEM part is being sold at a significantly lower price, it is likely counterfeit.

The Right Choice for Long-Term Value

Choosing between OEM and aftermarket parts requires a careful assessment of quality, cost, and risk tolerance. OEM parts offer reliability, manufacturer-backed warranties, and exact fit, making them ideal for industries where safety and precision are paramount. High-quality aftermarket parts, on the other hand, can provide cost-effective alternatives without compromising performance, but require thorough research before purchase.

At Acviss, we specialise in cutting-edge authentication and track-and-trace solutions to help businesses and consumers protect against counterfeit parts. From AI-powered digital verification to blockchain-based traceability, our solutions ensure that every part in your supply chain is genuine and secure.

Want to safeguard your brand and customers from counterfeit threats? Get in touch with us today to explore how our solutions can help.