Mass Encoding in QR Code Printing: How to Scale Efficient Labelling

Every product tells a story. But in today’s hyper-connected world, that story isn’t just printed on packaging, it’s encoded within a QR code. From pharmaceuticals and electronics to luxury goods and FMCG, QR codes have become the backbone of authentication, supply chain tracking, and consumer engagement. However, scaling QR code printing from a few thousand to millions while ensuring security, efficiency, and non-cloneability is a challenge that requires cutting-edge technology and precision execution.

The real question is: How do you print millions of QR codes while keeping them tamper-proof, non-replicable, and seamlessly integrated into global supply chains?

The answer lies in mass encoding, a sophisticated process that merges high-speed printing, encrypted data encoding, and AI-powered security measures.

The Science of Mass Encoding: How QR Codes Scale Without Compromising Security

Scaling QR code printing isn’t just about generating millions of codes and printing them in bulk. It involves real-time encoding, secure data handling, and inline verification to ensure every QR code remains unique, traceable, and impossible to counterfeit.

The Three Pillars of Secure Mass Encoding

1. Dynamic Data Encoding

- Each QR code is dynamically generated with unique identifiers: serial numbers, product batch details, and encrypted security layers.

- Unlike traditional barcodes, QR codes allow multi-layer data storage, embedding URLs, blockchain hashes, and authentication mechanisms.

- AI-based algorithms generate non-repeating codes, ensuring uniqueness across millions of labels.

2. High-Speed Printing & Inline Verification

- Industrial-grade thermal, laser, and UV inkjet printing ensure high-resolution QR codes that remain scannable in extreme conditions.

- Inline vision systems scan and verify every printed QR code in milliseconds, rejecting misprints or duplicates automatically.

- Machine learning-powered error detection analyses inconsistencies in QR patterns, reducing printing defects by over 99.9%.

3. Cloud-Based Traceability & Authentication

- Each QR code is securely linked to a cloud-based database, preventing duplication or unauthorised code regeneration.

- Consumers and supply chain partners can verify authenticity in real-time, reducing the risk of counterfeiting.

- Advanced AI-driven pattern recognition detects unusual scan activity, instantly flagging potential counterfeit attempts.

The Role of Mass Encoding in QR Code Printing

Mass encoding in QR code printing involves generating unique, secure, and non-replicable QR codes on a large scale, ensuring each label is tied to a specific product or packaging unit. Unlike simple batch printing, where QR codes may be pre-generated and printed in bulk, mass encoding involves dynamic, real-time data processing where each code is assigned based on predefined security parameters and integrated directly into the manufacturing or packaging line.

One of the key aspects of mass encoding isvariable data printing (VDP), which allows real-time generation and printing of unique QR codes with specific product details. This is critical in industries such as pharmaceuticals, where regulatory compliance requires each unit to have an individualised identifier that can be traced back to its origin.

Challenges in Scaling QR Code Printing (And How Technology Solves Them)

Despite the efficiency of QR codes, mass encoding presents several roadblocks that can compromise security, efficiency, and reliability. Here’s what goes wrong—and how advanced technology addresses it.

1. The Risk of QR Code Duplication and Tampering

A major challenge in mass encoding is counterfeiters cloning QR codes and redirecting them to fake websites or illegitimate supply chains. If a QR code isn’t encrypted or has a predictable pattern, it can be copied, printed, and used for fraud.

The Solution:

- Non-cloneable QR codes prevent unauthorised replication by embedding non-reproducible digital fingerprints.

- AI-driven scan tracking monitors QR usage, detecting unusual scanning patterns that could indicate fraud.

- Blockchain-based authentication ensures that each QR code remains unique and immutable throughout the product lifecycle.

2. Poor Print Quality Leading to Unscannable QR Codes

Printing millions of QR codes at high speed can lead to ink smudging, poor contrast, and alignment errors, making codes unreadable. A QR code that fails to scan is equivalent to a lost opportunity for authentication and engagement.

The Solution:

- Inline print verification systems scan every QR code immediately after printing, rejecting defective labels before they reach packaging.

- AI-powered auto-correction algorithms optimise QR size, contrast, and positioning for maximum readability.

- Laser-engraved QR codes for high-security applications ensure permanent, tamper-resistant marking.

3. Supply Chain Integration Bottlenecks

QR codes are only effective if they are seamlessly integrated into inventory management, tracking systems, and customer engagement platforms. Many businesses struggle with fragmented supply chain visibility, leading to data mismatches and verification failures.

The Solution:

- Cloud-synced QR codes allow real-time updates, ensuring accurate tracking from manufacturing to retail shelves.

- ERP and warehouse management integration links QR codes with inventory data, reducing stock errors and unauthorised product movement.

- AI-powered predictive analytics use QR scan data to optimise logistics and prevent grey market diversions.

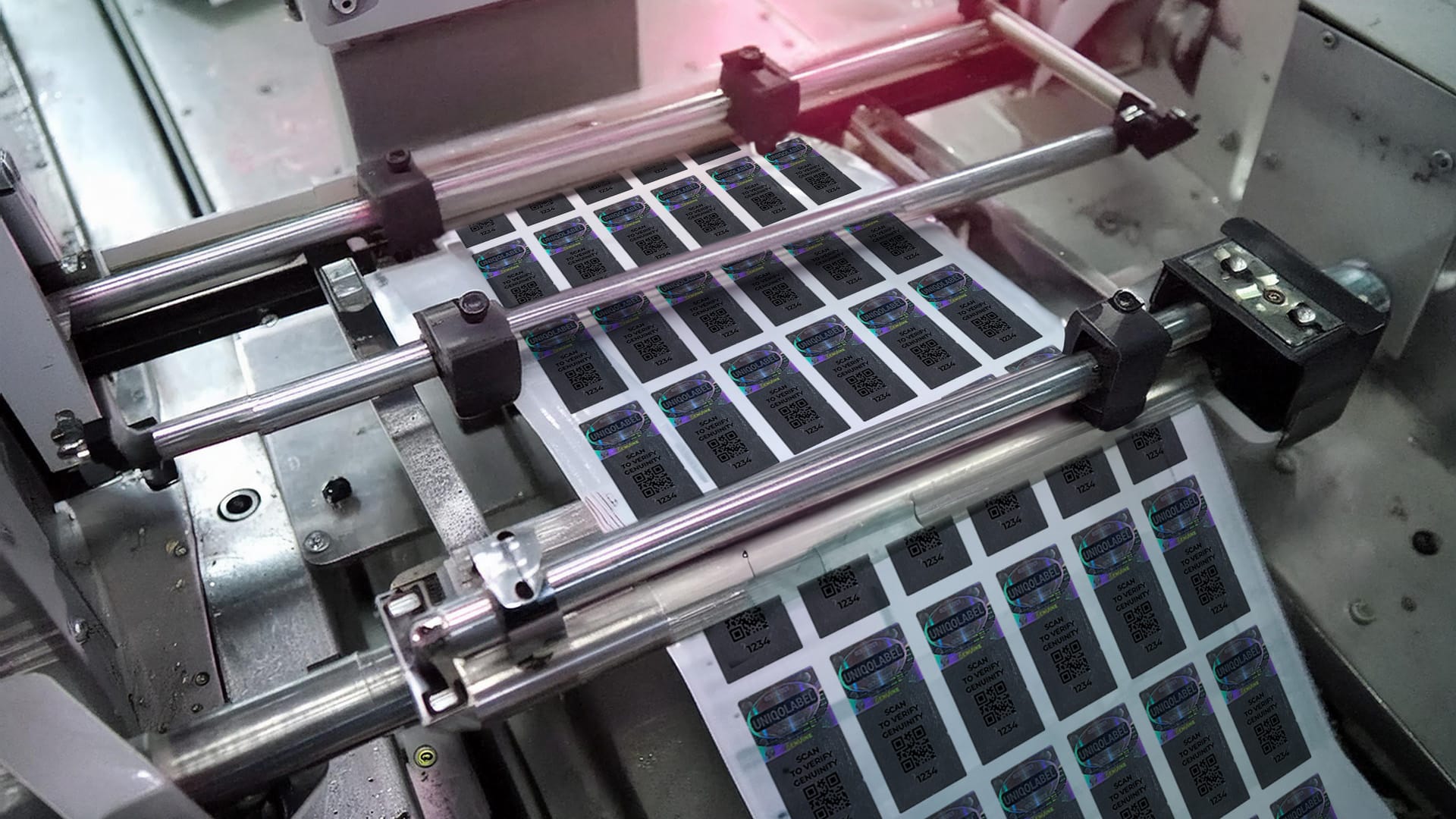

Optimising Print Efficiency for Large-Scale Operations

Printing QR codes at scale requires precision and high-speed printing capabilities. Industrial-grade printers equipped with inline printing technology allow seamless integration of QR code generation and printing directly onto product packaging or labels. Inline printing eliminates the need for pre-printed labels, reducing the risk of mismatched codes and enhancing efficiency.

To optimise print accuracy, high-resolution printing technologies such as laser marking and thermal inkjet printing are widely used. These methods ensure that QR codes maintain their integrity even in harsh environments, such as exposure to moisture, chemicals, or extreme temperatures. Moreover, automated verification systems are integrated within production lines to instantly check the readability of QR codes, minimising the risk of defective labels entering the market.

Integration with Supply Chain and Authentication Systems

For mass-encoded QR codes to be effective, they must be seamlessly integrated into the broader supply chain ecosystem. This involves connecting QR codes with centralised databases, enterprise resource planning (ERP) systems, and customer-facing authentication platforms.

In the pharmaceutical industry, for example, QR codes encoded with serialisation data help comply with regulations such as the Drug Supply Chain Security Act (DSCSA) and Falsified Medicines Directive (FMD). These regulations mandate that each drug unit must have a unique identifier that can be tracked throughout the supply chain to prevent counterfeit drugs from entering circulation.

Beyond regulatory compliance, mass-encoded QR codes also enable direct consumer interaction. Scanning a QR code, consumers can instantly verify product authenticity, access detailed product information, or even participate in loyalty programmes. This not only enhances security but also fosters brand trust and engagement.

The Future of Mass Encoding in QR Code Printing

As industries continue to demand higher levels of security, efficiency, and traceability, mass encoding in QR code printing will continue to evolve. AI-driven personalisation will enable brands to create highly dynamic QR codes that change based on consumer behaviour, purchase history, or even real-time environmental conditions.

Advancements in invisible QR codes and nanoprinting are also emerging, providing additional layers of security that are impossible to replicate with conventional printing methods. These technologies make it significantly harder for counterfeiters to reproduce authentic QR codes, further strengthening product security.

Moreover, with IoT-driven smart packaging, QR codes will not only act as digital identifiers but also interact with connected devices to provide real-time product status updates, environmental monitoring, and automated replenishment services.

Acviss’s Non-Cloneable Technology: The Future of Secure QR Code Printing

Traditional QR codes are vulnerable to cloning, allowing counterfeiters to replicate them easily. Acviss’s non-cloneable QR technology ensures each QR code is unique, tamper-proof, and impossible to duplicate, making mass encoding both secure and scalable.

How It Works

- Cryptographic Protection: Each QR code is encrypted, preventing unauthorised duplication.

- AI-Powered Anomaly Detection: Scans are monitored in real-time to detect fraud or unusual activity.

- One-Time-Use Authentication: QR codes become invalid after a single scan or a predefined number of uses.

- Blockchain-Backed Serialisation: Immutable records ensure genuine traceability and product authenticity.

- Instant Smartphone Verification: Consumers can verify authenticity instantly, enhancing trust and engagement.

Why It Stands Out

Feature | Conventional QR Codes | Acviss’s Non-Cloneable QR Codes |

|---|---|---|

Cloneability | Easily copied | Impossible to duplicate |

Encryption | Basic or none | Cryptographic security |

Tamper Detection | Not included | AI-based anomaly detection |

Blockchain Integration | Rarely used | Fully integrated |

Consumer Trust | Limited verification | Real-time authentication |

Conclusion

QR codes are no longer just marketing tools; they are the foundation of secure, scalable, and intelligent product authentication. But printing millions of QR codes without a secure mass encoding strategy leaves brands vulnerable to counterfeiting, supply chain fraud, and data leaks.

Secure your products at scale with Acviss’s non-cloneable QR code technology, because authenticity should never be compromised. Get in touch with us today!