Understanding Parent-Child Traceability in Packaging and Distribution Workflows

The packaging line is humming. Boxes are sealed, labelled, and stacked. Pallets are shrink-wrapped and loaded onto trucks. Everything looks like it’s moving smoothly, but can you pinpoint which product went where, and who it finally reached?

For many brands, the answer isn’t a confident yes. As supply chains grow more complex and regulatory demands tighten, the old ways of tracking products, spreadsheets, siloed systems, or legacy ERPs can’t keep up. In this environment, parent-child traceability has emerged as one of the most effective tools to ensure product traceability, protect intellectual property, and prevent counterfeiting throughout packaging and distribution workflows.

Yet the concept remains poorly understood by many business leaders, especially in fast-moving industries like pharmaceuticals, consumer electronics, and FMCG. This blog breaks it down, guiding you through how parent-child traceability works, why it matters, and how it supports brand protection, IP protection, and compliance objectives. If you're trying to build a resilient, transparent supply chain, you’ll want to keep reading.

What Is Parent-Child Traceability?

Think of parent-child traceability as a way of maintaining the hierarchy of packaging and logistics.

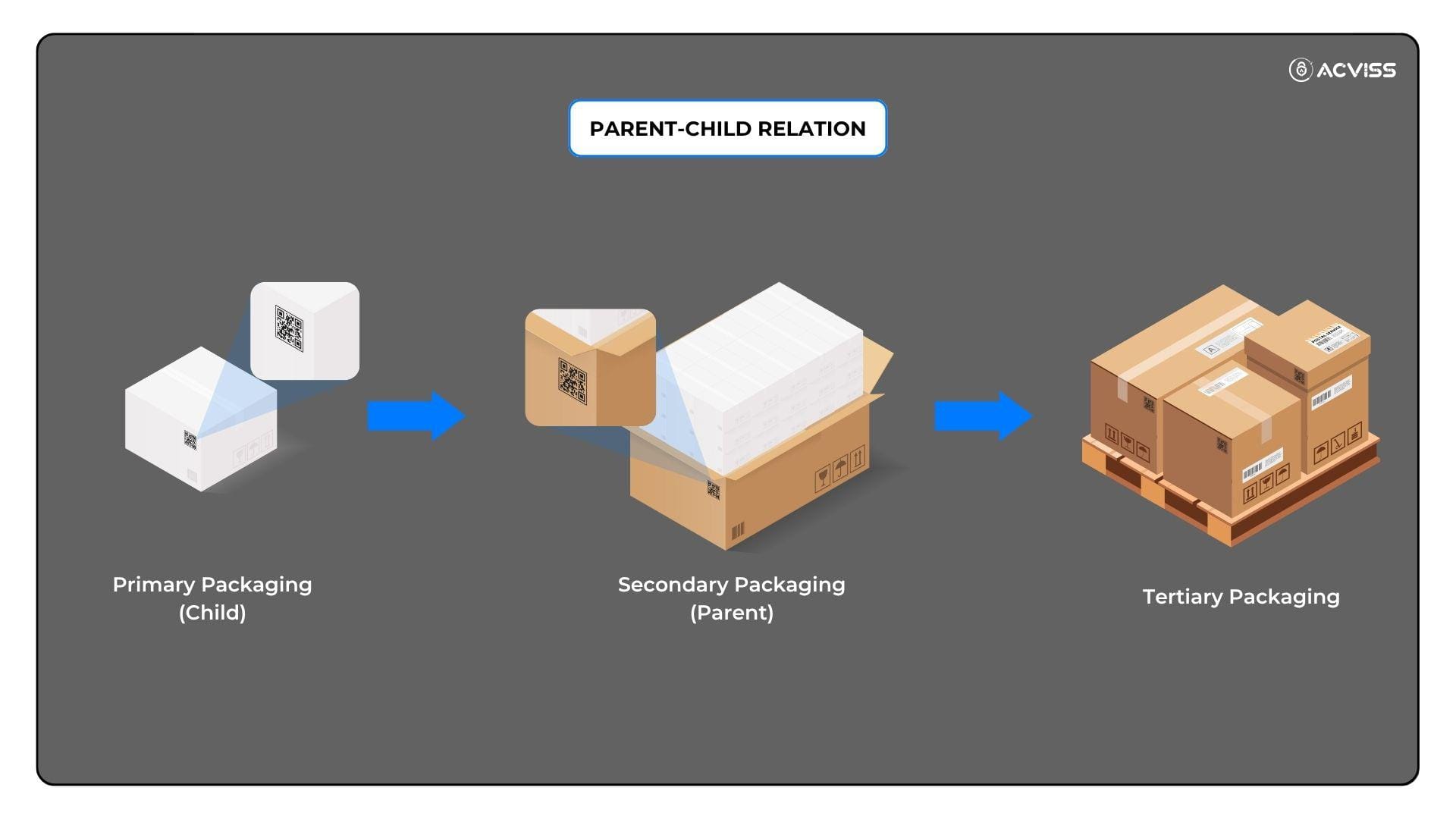

In simple terms:

- Child items are the smallest units, individual products, such as a bottle of shampoo or a box of tablets.

- Parent items are containers of child units, such as cartons, cases, or pallets.

Each child item is given a unique identifier, often a serial number or scannable code, and when these are grouped into a parent unit, that unit also receives its unique code. The system then logs the relationship between them.

If one carton (the parent) contains 50 bottles (children), that linkage is stored digitally. So, by scanning the parent, the system can instantly identify all associated children, and vice versa.

Why Does It Matter?

The benefits of parent-child traceability extend far beyond mere operational efficiency. For brands navigating global distribution, ever-changing regulatory landscapes, and rising incidents of counterfeiting, it can be the difference between chaos and control.

1. Full Supply Chain Visibility

With parent-child hierarchies, it’s possible to trace the full journey of a product, from factory floor to retail shelf. Every transfer, every repackaging, every scan is recorded, creating a digital thread that enhances transparency and accountability.

This is particularly vital in sectors where track and trace is not just an operational choice but a legal requirement. For example, pharmaceutical companies complying with the DSCSA in the US or FMD in Europe must demonstrate the origin, handling, and destination of each package.

2. Faster Recalls, Lower Risk

If a defect or contamination is identified, parent-child traceability allows for targeted recall. Instead of pulling thousands of products off shelves, companies can isolate affected batches within specific cartons or pallets and act quickly.

This mitigates both reputational and financial risk, a critical element of brand protection and consumer trust.

3. Effective Anti-Counterfeiting Solutions

Counterfeiters often target individual product units or attempt to infiltrate packaging layers at weak points. With parent-child traceability, the moment a mismatch is detected (e.g., a bottle claiming to be from carton A but missing from the digital registry), the product can be flagged as unauthorised.

Combined with product authentication technologies, such as secure QR codes, holograms, or digital fingerprints, this method provides a powerful, layered defence against fakes.

4. Smarter Warehousing and Logistics

By identifying every product’s position in the packaging hierarchy, logistics teams can locate, move, and audit stock with greater precision. For instance, scanning a pallet at the loading dock automatically records the IDs of all included units, reducing manual effort and improving data integrity.

This helps streamline fulfilment, manage returns, and optimise inventory, all while reducing human error.

How Parent-Child Traceability Works in Practice

To understand how it plays out in real-world packaging workflows, let’s look at a typical scenario:

Stage 1: Unit-Level Coding

Each product is affixed with a unique identifier, usually a barcode, QR code, or Data Matrix, during production. This is the child code.

Stage 2: Aggregation

When products are packed into cartons or cases, a parent code is generated for the carton. The relationship between parents and children is established digitally. This process is called aggregation.

At higher levels, multiple cartons may be packed onto a pallet, forming a grandparent-parent-child hierarchy. The key is that every level is linked.

Stage 3: Distribution and Scanning

When the parent is scanned at any checkpoint, warehouse, customs, or distributor, the system reads and logs all nested child codes. Any tampering or removal of units triggers an alert if the codes don’t match.

Stage 4: Market-Level Verification

If a consumer or retailer scans an individual product, the system can validate its origin by checking the child code’s association with its parent. If it doesn’t belong or hasn’t been registered, it could indicate a fake.

To support such aggregation, companies are increasingly turning to advanced, modular solutions. Platforms like Acviss Origin provide end-to-end track and trace capabilities across multiple packaging layers. Powered by blockchain, Origin not only secures the integrity of parent-child relationships but also ensures tamper-evident and immutable data trails, ideal for brands serious about IP protection, brand verification, and compliance readiness.

Challenges in Implementing Parent-Child Traceability

While the benefits are clear, implementation can be daunting, especially for brands operating across diverse geographies and multiple contract manufacturers.

1. Data Management Complexity

With thousands (or millions) of SKUs moving through the supply chain, storing and managing parent-child relationships requires robust back-end infrastructure. Brands must ensure their traceability solution can scale without compromising speed or data integrity.

2. Hardware Integration

Aggregation often requires specialised printers, vision systems, and scanning stations. Seamless integration into existing packaging lines takes careful planning and coordination with equipment providers.

3. Standards and Interoperability

Without adherence to global standards (such as GS1), traceability data may not be readable across stakeholders. Brands must ensure interoperability across platforms to enable the smooth exchange of authentication and tracking data.

4. Training and Compliance

Human error is a major risk factor. Operators must be trained not only in the technical workflows but also in understanding how errors in aggregation can impact everything from product verification to legal compliance.

The Role of Traceability in Brand Protection and IP Defence

Parent-child traceability isn’t just about logistics, it plays a vital role in trademark protection, IP protection, and brand authentication.

When counterfeiters replicate products, it’s not just revenue loss brands suffer. It's a loss of consumer trust, legal challenges over fake warranties, and often, irreversible damage to a brand’s image. By integrating product-level serialisation with packaging-level traceability, brands build a digital wall that’s difficult to breach.

Moreover, brands that establish transparent traceability protocols are in a stronger position to enforce trademarks and IP. In disputes or customs seizures, being able to prove a product’s origin and packaging trail strengthens your legal defence significantly.

How to Get Started: Key Considerations

If you’re looking to implement parent-child traceability, start with the following checklist:

- Evaluate Your Current Supply Chain

Identify the points where aggregation is possible and determine your current gaps in visibility. - Choose Scalable Technology Partners

Look for track and trace solutions that offer real-time aggregation, seamless hardware integration, and standards compliance. - Consider Brand Protection as a Core Objective

Traceability should be viewed not just as an operational tool but as a shield for your brand identity. - Prepare Your Teams

Train your staff across manufacturing, QA, warehousing, and IT to manage and maintain aggregation protocols. - Integrate with Authentication

Linking traceability with secure product authentication systems gives you a double-layered defence against fakes and grey market activity.

Ready to Take the Next Step?

Parent-child traceability is more than just a packaging protocol; it’s a strategic move toward better supply chain control, stronger brand protection, and a more resilient business model.

Interested to learn more? Get in touch with us.

We’d be happy to walk you through how solutions like Acviss Origin can help your business achieve traceability without the complexity.