The Coming Wave of Hyper-Personalised Manufacturing and the Need for Authenticity

Manufacturing is no longer shaped solely by scale, efficiency, or cost. It is being reshaped by intimacy. Products are increasingly designed for one customer, one context, one moment. From pharmaceuticals tailored to patient profiles to consumer goods produced in batches of one, the era of hyper-personalised manufacturing is no longer a future concept. It is a structural shift already underway.

This transformation brings undeniable opportunity. It also introduces new fragilities. As manufacturing fragments into microfactories, as supply chains regionalise, and as data becomes the raw material of production, one question rises above the rest: how do brands maintain authenticity, trust, and product integrity in a market where every product may be different?

For brand owners, leadership teams, and supply chain decision-makers, this is not a philosophical concern. It is a commercial one.

From uniformity to individuality: the manufacturing shift underway

For over a century, mass production rewarded sameness. Standardised products, centralised factories, and long production runs allowed manufacturers to drive down unit costs and dominate global markets. That logic is now eroding.

Consumers today expect relevance. They want products that fit their needs, preferences, and values, without waiting months or paying prohibitive premiums. This expectation has driven the rise of mass customisation and, more recently, hyper-personalisation.

The operational shift is profound:

Manufacturing is moving from make-to-stock to assemble-to-order and make-to-order models.

Tooling is becoming digital, modular, and reconfigurable rather than rigid and capital-intensive.

Production volumes are shrinking per SKU, even as overall output grows.

Additive manufacturing, rapid tooling, and AI-driven planning now allow manufacturers to produce customised products at near-mass production costs. Footwear with personalised insoles, medical devices tuned to patient data, and personalised packaging runs are no longer niche experiments. They are becoming mainstream.

Data support this momentum. Industry studies suggest that companies implementing mass customisation strategies can achieve revenue increases of 5 to 15 per cent, while reducing inventory holding costs by up to 30 per cent.

Hyper-personalisation raises the bar beyond customisation

Standard personalisation relies on segments. Hyper-personalisation operates at the level of the individual.

This distinction matters. Hyper-personalised manufacturing draws on real-time behavioural data, contextual signals, and AI-driven decision-making to shape not just marketing messages, but the product itself. The factory floor becomes responsive to customer data.

In pharmaceuticals, this trend is particularly visible. Dosage forms, packaging, and even delivery mechanisms are increasingly adapted to patient profiles, compliance behaviour, and regulatory requirements. Product authentication in pharma is no longer just about safety. It is about ensuring that a highly specific product reaches the right patient, in the right condition, with full verification.

Yet the closer manufacturing moves to the customer, the more exposed it becomes.

The authenticity challenge in a fragmented manufacturing world

Hyper-personalisation introduces complexity at every layer of the supply chain. When products are produced in smaller batches, across distributed microfactories, the traditional markers of authenticity weaken.

Uniform packaging, consistent batch identifiers, and centralised quality control no longer offer sufficient assurance. This creates three interconnected risks.

First, the rise of counterfeit opportunity

Fragmentation creates seams, and seams are where counterfeiting thrives. As production spreads across regions and partners, counterfeiters exploit inconsistencies in labelling, verification, and supply chain visibility.

In sectors such as pharma, cosmetics, agrochemicals, and electronics, counterfeit penetration already accounts for an estimated 3 to 5 per cent of global trade. Hyper-personalised manufacturing, without strong brand protection solutions, risks widening that gap.

Second, erosion of consumer trust

Customers may accept variation, but they will not accept uncertainty. If a personalised product cannot be easily authenticated or verified, confidence erodes. This is particularly critical where product safety is involved.

Studies show that over 70 per cent of consumers are more likely to remain loyal to brands that offer transparent product verification mechanisms. In a hyper-personalised environment, trust must be engineered into every unit, not just communicated through marketing.

Third, regulatory exposure

Regulatory frameworks such as EUDR, pharmaceutical traceability mandates, and evolving IP protection requirements are tightening. Hyper-local production does not dilute regulatory responsibility. It amplifies it.

Product traceability, track and trace capabilities, and real-time supply chain management are becoming non-negotiable, not optional enhancements.

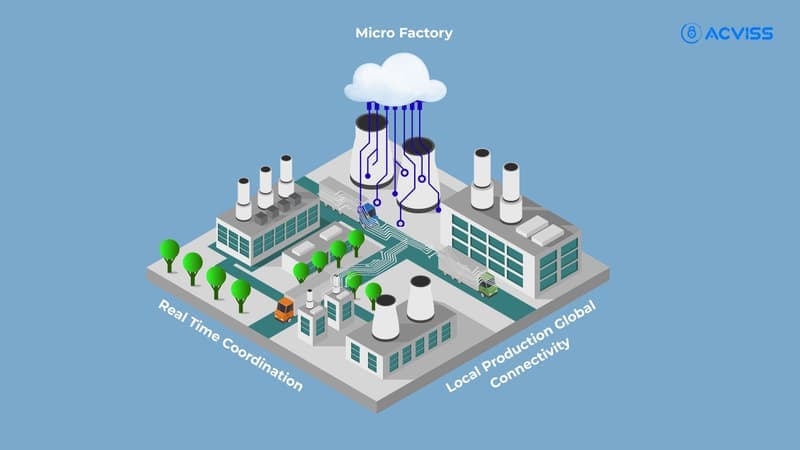

Smart microfactories change the rules of control

The shift toward microfactories is often framed as a cost or sustainability decision. In reality, it is a control decision.

Microfactories are smaller, modular, and heavily automated. They sit closer to demand centres, reducing logistics costs and carbon exposure. They are also designed for rapid reconfiguration, enabling manufacturers to respond to volatile demand.

However, control in this model does not come from physical oversight. It comes from data, identity, and verification.

In distributed manufacturing, the brand’s authority must travel with the product. That authority is expressed through digital identities, secure authentication markers, and verifiable production records.

This is where modern brand protection technologies become infrastructure, not add-ons.

Authenticity as a system, not a label

Maintaining authenticity in hyper-personalised manufacturing requires a shift in mindset. Authenticity is no longer a static attribute applied at the end of production. It is a system embedded across the lifecycle.

1. Product authentication at the unit level

When every product is different, verification must operate at the individual unit level. Non-cloneable technologies, designed to resist replication, provide a foundation for this approach. Unlike traditional serialisation, these markers cannot be copied at scale, making them suitable for highly variable production environments.

Such mechanisms allow customers, regulators, and partners to verify product authenticity instantly, using simple digital interactions.

2. Product verification across the supply chain

Authentication alone is insufficient if it is disconnected from the supply chain. Track and trace systems link each product’s identity to its movement, handling, and transformation.

In hyper-personalised manufacturing, track and trace becomes dynamic. Production data, quality parameters, and logistics events are continuously updated, enabling real-time product traceability.

This is especially relevant for pharma and regulated industries, where deviations can carry serious consequences.

3. Brand verification in the hands of the customer

One of the most significant shifts in recent years is the movement of verification power toward the end customer. Brand authentication is no longer a back-office function.

When customers can independently verify products, trust increases, engagement improves, and counterfeit circulation declines. Research indicates that brands offering consumer-facing verification see measurable gains in customer satisfaction and repeat purchase intent.

Data, trust, and the limits of personalisation

Hyper-personalisation depends on data. Trust depends on how that data is handled.

There is a narrow line between relevance and intrusion. While 76 per cent of consumers express frustration with generic experiences, they also expect transparency around data usage. Brands that fail to communicate how personal data informs manufacturing decisions risk reputational damage.

From a manufacturing perspective, this reinforces the need for logical data management. Data must be actionable, secure, and purpose-bound. Digital twins, AI-driven planning, and real-time quality control rely on transient data flows, not monolithic data lakes.

Yet every data-driven decision must be auditable. Authenticity is inseparable from accountability.

The strategic role of brand protection in this new era

Brand protection has historically been reactive. In the era of hyper-personalised manufacturing, it becomes strategic.

Authentication, verification, and traceability systems act as the connective tissue between personalisation and trust. They allow brands to scale individuality without losing control.

Within this context, solutions such as Certify enable product authentication at the unit level, ensuring that personalised products remain verifiable without friction. Origin supports end-to-end product traceability, linking manufacturing events to supply chain movement and regulatory reporting. Non-cloneable technologies underpin both, providing resilience against counterfeiting in highly variable production environments.

These capabilities do not replace manufacturing innovation. They stabilise it.

Why leadership teams must act now

The coming wave of hyper-personalised manufacturing will not arrive evenly. Early adopters will gain a disproportionate advantage, while late movers will struggle to retrofit trust into fragmented systems.

For leadership teams, the questions are strategic:

Can your current supply chain management framework support product-level verification at scale?

How will your brand maintain IP protection and trademark protection when production is decentralised?

Are your customers equipped to authenticate and verify the products they receive?

Ignoring these questions does not slow the shift. It only increases exposure.

Personalisation without trust is not progress

Hyper-personalised manufacturing represents a genuine leap forward. It promises relevance, efficiency, and resilience in a volatile global environment. Yet personalisation without authenticity is fragile.

The brands that succeed will be those that treat product authentication, brand verification, and anti-counterfeiting solutions as core manufacturing capabilities, not defensive afterthoughts. They will recognise that trust is manufactured alongside the product, not after it leaves the factory.

As manufacturing becomes more human in its output, it must become more rigorous in its foundations.

Interested to learn more about building authenticity into hyper-personalised manufacturing? Get in touch with us to explore how robust brand protection, product verification, and track and trace solutions can support your next phase of growth.