Understanding Different Types of Product Packaging: A Complete Guide

Packaging more than just a protective shell is the first interaction a customer has with your product. It influences purchasing decisions, ensures product integrity and even plays a role in combating counterfeiting. Whether you’re in food, cosmetics, pharmaceuticals, or e-commerce, choosing the right packaging is essential for branding, compliance, and consumer trust.

Importance of Product Packaging

The significance of packaging extends far beyond aesthetics. The global packaging market size reached US$ 1.24 trillion in 2024.

Packaging serves as a crucial component in ensuring product safety, brand recognition, and consumer engagement. First and foremost, it acts as a protective barrier, shielding the product from environmental factors such as moisture, contamination, and physical damage during transport and storage. In industries like pharmaceuticals and food, where product integrity directly affects consumer health, the right packaging can prevent spoilage and contamination.

From a marketing perspective, packaging plays a pivotal role in brand identity. The colours, typography, and design elements of a package influence consumer perception and decision-making. Successful brands like Toblerone and Pringles leverage innovative packaging to create a memorable shopping experience that enhances customer loyalty.

Regulatory compliance is another essential aspect. Various industries must adhere to packaging laws and safety regulations that ensure the product meets legal requirements. For instance, child-resistant caps are mandated for hazardous substances, while food-grade materials are necessary for consumable products.

Primary, Secondary, and Tertiary Packaging

Understanding the classification of packaging can help businesses optimise their supply chain, improve logistics, and enhance the user experience. Packaging is typically divided into three main levels, each serving a distinct function.

1. Primary Packaging

Primary packaging is the first layer that comes in direct contact with the product. It is designed to protect the product from contamination while also making it convenient for consumers to use. A well-designed primary package should enhance the shelf life of perishable goods and provide clear information about the product, such as ingredients, expiry date, and usage instructions.

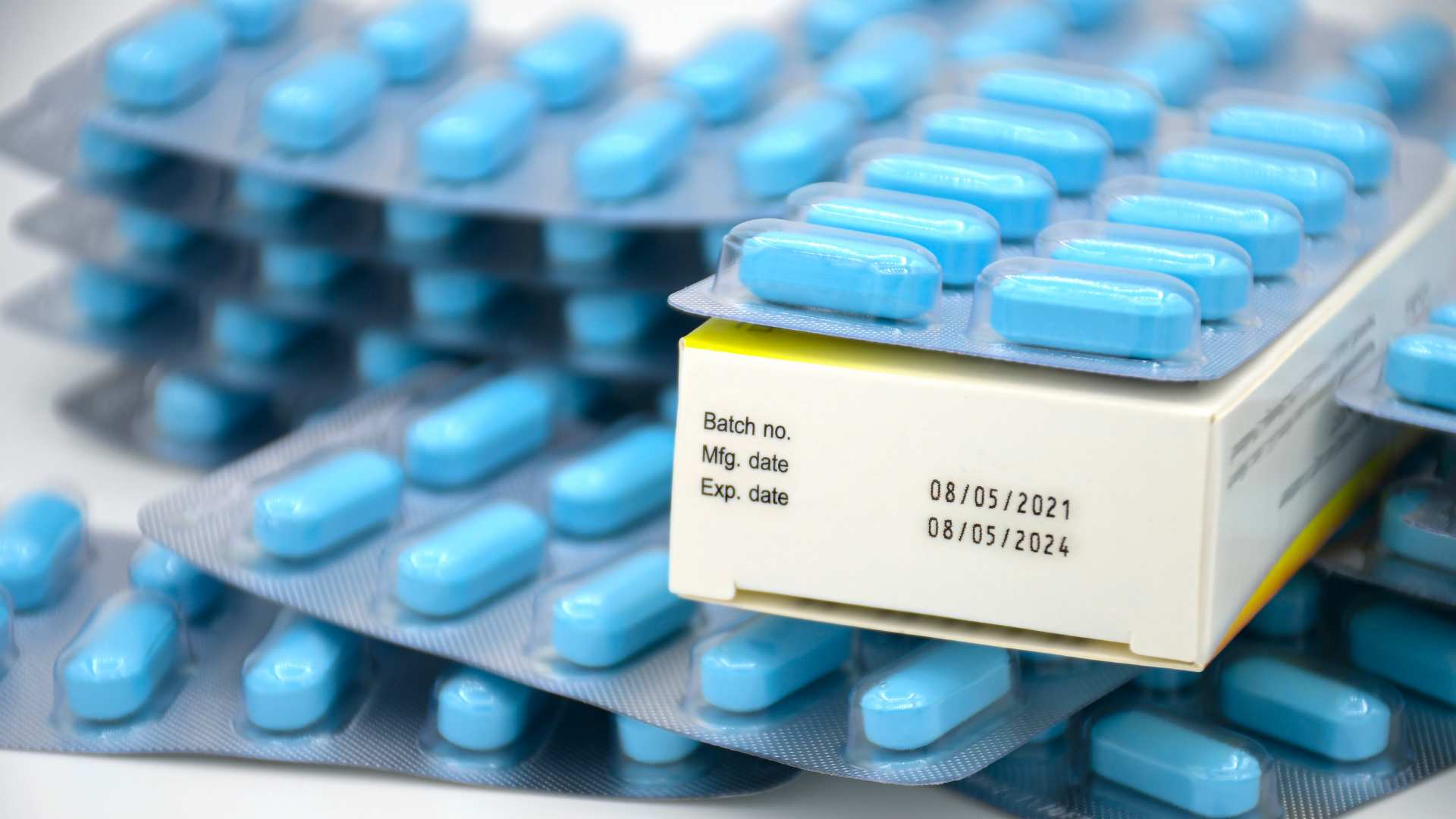

For example, in the food industry, a cereal box contains an inner plastic or foil pouch that keeps the cereal fresh. In the pharmaceutical industry, blister packs provide individual doses of medication while ensuring tamper evidence. Cosmetics often come in tubes, jars, or pump bottles that not only maintain product integrity but also improve ease of application.

2. Secondary Packaging

Secondary packaging is the additional layer that holds one or more primary packaging units together. This type of packaging is essential for branding, grouping products for retail display, and improving transportation efficiency. Multiple beverage cans may be packaged together in a cardboard box for easier handling. Similarly, pharmaceutical bottles are often placed in paperboard cartons that provide space for branding and additional product information.

Beyond branding, secondary packaging also adds an extra layer of protection against external factors such as moisture and rough handling during distribution. It helps standardise product quantities for retailers and allows for bulk sales without compromising product quality.

3. Tertiary Packaging

Tertiary packaging is used for bulk transportation and storage, primarily in warehouses and during shipping. Unlike primary and secondary packaging, tertiary packaging is rarely seen by consumers but plays a vital role in logistics. It includes pallets, shrink wrap, and large cartons that help in the safe and efficient movement of goods across supply chains. A well-structured tertiary packaging system minimises product damage and maximises storage efficiency, ensuring that items reach retailers in optimal condition.

How Packaging Facilitates Anti-Counterfeiting

Counterfeiting is a growing concern in industries such as pharmaceuticals, luxury goods, and electronics. Fake products result in revenue loss and pose significant risks to consumer health and brand reputation. To combat this issue, companies are integrating smart packaging solutions that offer product authentication and trackability.

One of the most common anti-counterfeiting measures is tamper-evident packaging.

This includes security seals and breakable caps that provide clear indications if a product has been tampered with. Holograms and watermarks are also frequently used, as they are difficult to replicate and serve as a visual marker of authenticity.

Advanced solutions; QR codes and serialisation allow consumers to verify a product’s authenticity by scanning the packaging with a smartphone. This technology enables brands to provide real-time tracking, ensuring that products remain within legitimate distribution channels. Combined with this, blockchain-based track-and-trace systems create an immutable record of a product’s journey from manufacturing to the consumer, further reducing the risk of counterfeiting.

Types of Packaging Used in Different Industries and Product Types

Different industries require specific packaging solutions to meet regulatory standards, preserve product quality, and enhance consumer experience. The choice of packaging depends on factors such as the product’s fragility, shelf life, and transportation requirements.

1. Food and Beverage Packaging

The food and beverage industry depends on packaging to maintain product freshness, safety, and convenience while ensuring compliance with health standards. Different packaging materials and formats cater to specific product needs, enhancing shelf life and consumer experience.

- Glass bottles and jars: A staple for beverages, sauces, and pickled products, glass is non-reactive, preserving the original taste and quality. It’s also highly recyclable, making it a sustainable choice for premium and long-lasting packaging.

- Aluminium cans: Widely used for carbonated drinks, juices, and energy beverages, aluminium provides a lightweight, shatterproof, and fully recyclable packaging solution. It offers excellent protection from light and oxygen, preserving flavour and carbonation.

- Tetra packs: A multi-layered packaging format commonly used for dairy products, juices, and plant-based beverages. These packs offer an extended shelf life without refrigeration, making them cost-effective and eco-friendly with recyclable options.

- Vacuum-sealed pouches: Designed for perishable food items like meat, seafood, and ready-to-eat meals, these pouches remove oxygen to prevent bacterial growth, ensuring freshness and longer shelf life.

- Flexible plastic films: A go-to solution for snack foods, frozen meals, and bakery items, these films provide lightweight, moisture-resistant, and cost-effective packaging. Many brands are now transitioning to biodegradable and compostable alternatives to reduce environmental impact.

2. Pharmaceutical Packaging

Pharmaceutical packaging plays a crucial role in ensuring drug safety, regulatory compliance, and accurate dosage control. With strict requirements for sterility and tamper resistance, packaging solutions in this sector are designed for security and ease of use.

- Blister packs: Commonly used for tablets and capsules, blister packs offer individual dose protection, preventing contamination while making it easy for patients to track their medication intake.

- Ampoules and vials: Essential for liquid medications, injectables, and vaccines, these glass or plastic containers ensure sterility and controlled dosing. Many vials now come with self-sealing caps for added protection.

- Child-resistant bottles: A critical safety feature for prescription and over-the-counter medicines, these bottles are designed with push-and-turn caps to prevent accidental ingestion by children.

- Cold chain packaging: Necessary for temperature-sensitive pharmaceuticals like vaccines and biologics, cold chain packaging uses insulated containers, gel packs, and real-time monitoring to maintain required temperatures during transport.

3. Cosmetic and Personal Care Packaging

A blend of aesthetics and functionality, cosmetic packaging is designed to protect beauty and personal care products while enhancing brand appeal. Sustainable and reusable options are gaining popularity in response to growing environmental concerns.

- Pump bottles and tubes: Ideal for skincare, haircare, and personal hygiene products, these containers ensure easy application while minimising waste and contamination. Airless pumps are increasingly used for premium formulations.

- Compact cases and jars: A staple for makeup products like foundations, powders, and creams, these cases often include built-in mirrors and applicators for convenience.

- Glass containers: Preferred for perfumes, serums, and high-end skincare, glass packaging offers durability, chemical stability, and a premium look. Tinted glass also protects light-sensitive formulations.

- Sachet packaging: Common for sample products and travel-friendly options, sachets offer a single-use format that helps customers try products before committing to full-sized versions.

4. E-commerce and Retail Packaging

With the rise of online shopping, packaging for e-commerce needs to be durable, secure, and cost-effective while also supporting sustainability initiatives. Consumer expectations for an enhanced unboxing experience are shaping packaging trends.

- Corrugated cardboard boxes: The most widely used packaging for shipping, these boxes provide structural strength while being lightweight and recyclable. Many brands opt for custom branding to improve customer experience.

- Bubble mailers and padded envelopes: Ideal for small and fragile items like electronics, accessories, and books, these mailers add a cushioning layer to absorb shocks during transit.

- Tamper-proof security bags: Used for high-value items like jewellery, pharmaceuticals, and electronic devices, these bags feature security seals that provide visible tamper evidence.

- Returnable packaging: A growing trend in sustainable e-commerce, returnable packaging includes reusable mailing bags and boxes, allowing customers to return packaging for reuse, reducing waste and costs.

5. Industrial and Logistics Packaging

Industrial packaging focuses on bulk storage, secure transport, and efficiency in handling large-scale shipments. These packaging solutions need to be sturdy, reliable, and adaptable for different industries.

- Wooden crates and pallets: Used for transporting heavy machinery, automotive parts, and industrial goods, these provide robust protection while enabling easy stacking and handling.

- Shrink wrap and stretch films: Essential for securing products on pallets during transit, these films prevent shifting, protect against dust and moisture, and enhance load stability.

- Intermediate bulk containers (IBCs): Designed for transporting and storing liquids, chemicals, and bulk food ingredients, IBCs come in various capacities and are often stackable and reusable for efficiency.

Factors Influencing the Packaging Choice

Several factors come into play when selecting the most suitable packaging for a product.

- Product: One of the primary considerations is the nature of the product itself. Fragile items require extra cushioning and protective layers, whereas food products need packaging that maintains freshness and prevents spoilage.

- Consumer Preference: The taste and preferences of consumers influence packaging decisions. Convenience is a major selling point today. Easy-to-open and resealable packaging designs enhance user experience and increase product appeal. Sustainability is becoming a priority, with many brands opting for recyclable or biodegradable materials to reduce environmental impact.

- Regulatory compliance: Certain industries, such as pharmaceuticals and food, must adhere to strict packaging guidelines to ensure consumer safety. EUDR and DPP mandate brands to use packaging that meets the industry standards and is sustainable. Non-compliance with such regulations can result in legal issues leading to damage to reputation, loss in market share and customer loyalty.

From a logistical perspective, cost-effectiveness and supply chain efficiency must be considered. Lightweight materials can reduce transportation costs, while stackable packaging designs improve storage space utilisation.

How Packaging Plus Anti-Counterfeiting Solutions is Critical

Packaging plays a vital role in protecting products from tampering, substitution, and duplication. Beyond its primary function of safeguarding the product, it serves as the first layer of defence against counterfeiting. Effective anti-counterfeit packaging integrates physical security features with digital authentication technologies to create a multi-layered protection system. Some key packaging solutions include:

1. Tamper-Evident Packaging

Tamper-evident packaging provides visible signs of interference, alerting consumers and retailers if a product has been altered. Common tamper-evident features include:

- Void seals and labels: Leave a “VOID” message or pattern when removed, indicating tampering.

- Breakable seals and tear strips: Designed to break upon first use, preventing resealing.

- Shrink bands and sleeves: Applied around the packaging to provide a clear indication if the product has been opened.

- Frangible labels: Made from brittle materials that disintegrate when an attempt is made to remove them.

2. Holographic and Optical Security Elements

Holograms and optical variable devices (OVDs) offer a visually striking authentication method that is difficult to replicate. These include:

- 2D and 3D holograms: Display different images when viewed from different angles.

- Kinetic effects and colour-shifting inks: Create movement or colour changes under light.

- Nano and micro-text features: Invisible to the naked eye but detectable under magnification.

3. Smart Packaging and Digital Authentication

Smart packaging leverages digital technology to provide real-time authentication and track-and-trace capabilities. Some of the leading technologies include:

- QR codes and unique alphanumeric codes: Consumers can scan these with a smartphone to verify authenticity via a brand’s official platform.

- RFID (Radio Frequency Identification) tags: Enable real-time tracking of products throughout the supply chain, helping prevent grey market diversion.

- NFC (Near Field Communication) chips: Allow consumers to authenticate products by simply tapping their smartphones against the packaging.

- Blockchain-based verification: Ensures an immutable and transparent record of a product’s journey from manufacturer to consumer.

4. Covert and Forensic Security Features

Covert security features are hidden elements that require specialised tools to verify authenticity. These include:

- UV and infrared inks: Only visible under UV or IR light, making them difficult for counterfeiters to detect and reproduce.

- Microtaggants and DNA markers: Custom-engineered molecular markers embedded into packaging materials that can be identified using specialised readers.

- Invisible watermarks: These can be revealed through digital processing or specific viewing conditions.

Acviss Certify: An Advanced Anti-Counterfeiting Solution

Acviss Certify provides a cutting-edge approach to packaging-based authentication by embedding non-cloneable security codes into packaging. This solution enables customers to verify the authenticity of a product instantly through a simple scan, using a mobile app or a web-based platform.

Key benefits of Acviss Certify include:

- Instant consumer verification: Customers can check a product’s genuineness in real-time.

- Non-replicable security technology: Unique codes prevent duplication by counterfeiters.

- Real-time tracking and analytics: Brands gain insights into product movement and consumer interactions.

- Seamless integration with packaging: Works with labels, cartons, and flexible packaging without requiring significant changes to manufacturing processes.

Final Thoughts

Product packaging has evolved beyond its traditional role of mere containment. It is now a vital tool for branding, security, and sustainability. Integrating anti-counterfeiting measures into packaging design is no longer optional but a necessity for brands looking to maintain authenticity and market credibility.

At Acviss, we specialise in securing your product and brand with cutting-edge anti-counterfeiting and packaging solutions that provide instant verification, real-time tracking, and non-cloneable security.

Connect with us today to explore how our packaging and authentication technologies can help you secure your products and strengthen your brand’s reputation.