India vs China: Where Should You Manufacture in 2025?

For decades, China stood as the undisputed titan of global manufacturing, a country synonymous with mass production, low labour costs, and unmatched scalability. However, as the world transitions into a new phase of economic, geopolitical, and technological complexity, this status quo is rapidly shifting. Small and medium-sized businesses (SMBs), once heavily reliant on China’s robust supply chains, are increasingly asking a pivotal question: Should we continue manufacturing in China, or pivot to India?

This blog examines this critical decision through a detailed, data-backed lens. If you're a founder, supply chain strategist, or product head evaluating the future of your manufacturing footprint, read on.

The China Conundrum: Manufacturing's Shifting Giant

1. Rising Costs and Regulatory Tightening

The low-cost narrative that propelled China to the top of the global manufacturing hierarchy is no longer a given. Over the past decade, wages have more than doubled. As of 2025, a manufacturing worker in Shanghai earns a minimum of CNY 2,690 per month. Private sector wages are now averaging over $10,000 per annum, a stark contrast to manufacturing hubs like Vietnam and India, where costs are nearly 50% lower.

In parallel, China is implementing stricter environmental and labour regulations. Compliance isn’t optional; factories failing emissions audits or labour inspections risk shutdowns and legal penalties. For SMBs, this means navigating a regulatory minefield while absorbing rising operational overhead.

2. Tariffs, Trade Wars, and Geopolitical Headwinds

Escalating geopolitical tensions are reshaping global supply chains. U.S. tariffs on Chinese imports have doubled to 20% in 2025, and China has retaliated with its levies on American goods. Regulatory measures like the EU's Carbon Border Adjustment Mechanism (CBAM) are further complicating cross-border trade for carbon-intensive Chinese manufacturers.

The increasing scrutiny on cybersecurity and rare earth exports has turned manufacturing in China into a strategic liability for companies in sensitive sectors like electronics, automotive, and telecom.

3. Persistent IP and Quality Concerns

Intellectual Property (IP) theft and quality inconsistencies continue to plague manufacturers in China. While legal frameworks exist and China is a signatory to major international treaties, enforcement is inconsistent. Several cases have surfaced where manufacturers duplicated proprietary designs or substituted materials without client approval, damaging brand reputation and customer trust.

India Rising: Is It the New Manufacturing Frontier?

India, often viewed as a sleeping manufacturing giant, is now fully awake. A confluence of factors, policy initiatives, demographic advantages, infrastructure improvements, and economic liberalisation is turning India into a viable alternative to China.

1. Competitive Labour and Abundant Workforce

India has emerged as one of the most cost-effective manufacturing bases globally. Manufacturing wages are significantly lower than China’s, yet the country boasts a large, skilled workforce with strong English proficiency, an added benefit for global coordination.

Unlike Southeast Asia, where labour shortages are emerging, India offers scale. From electronics and automotive to textiles and pharmaceuticals, India’s labour pool is not just cheaper but increasingly better trained.

2. Pro-Business Policies and Incentives

Government-backed initiatives such as ‘Make in India’ and Production Linked Incentive (PLI) schemes are providing strong financial incentives for foreign manufacturers. These policies span across electronics, automotive, defence, and pharmaceutical sectors, previously dominated by Chinese exports.

India’s simplified digital incorporation process and improved ranking in the World Bank’s Ease of Doing Business Index have made company formation more efficient and transparent.

3. Infrastructure and Market Access

Yes, India’s logistics infrastructure has historically lagged behind China's. However, strategic investments in industrial corridors, expressways, dedicated freight corridors, and port modernisation are closing that gap. SEZs like the one in Chennai offer plug-and-play infrastructure, reducing setup costs and lead times.

Moreover, India’s geographic location offers manufacturers a logistical sweet spot for serving the Middle East, Africa, and Southeast Asia. Combined with a massive domestic market (the fifth-largest economy and counting), India provides dual access to export and consumption-driven growth.

5. A Case in Point

No company embodies precision, secrecy, and logistical scale quite like Apple. For years, Apple relied almost entirely on Chinese partners like Foxconn and Pegatron. But in a strategic pivot, Apple has shifted 20–25% of its iPhone production to India as of early 2025.

Apple’s contract manufacturers have invested billions in Indian facilities. Foxconn, for instance, is building a $1.5 billion plant in Karnataka. Why? Because India offers:

A skilled labour force

Cost efficiency

Improved infrastructure

Government incentives under schemes like PLI (Production Linked Incentives)

This move is symbolic; it shows that even the most quality-obsessed brands trust India with flagship products.

India vs. China: A Strategic Comparison

Factor | India | China |

|---|---|---|

Labor Costs | Among the lowest globally | Rising rapidly, less cost-competitive |

Infrastructure | Improving, gaps still remain | Advanced and integrated |

Regulatory Environment | Transparent legal system, democratic checks | Centralised and policy-driven, subject to geopolitical shifts |

IP Protection | Strong enforcement, police powers for counterfeit raids | A legal framework exists, but enforcement remains weak |

Environmental Compliance | Fewer hurdles, growing sustainability focus | Strict and rising costs for compliance |

Government Incentives | PLI, Make in India, SEZs | Local subsidies but opaque processes |

Logistics/Proximity | Strategic for South Asia, the Middle East, and Africa | Stronger global logistics network |

Trade Relations | Stable with Western nations, favourable FTAs | Increasingly strained with the West |

Beyond India and China: Are There Other Contenders?

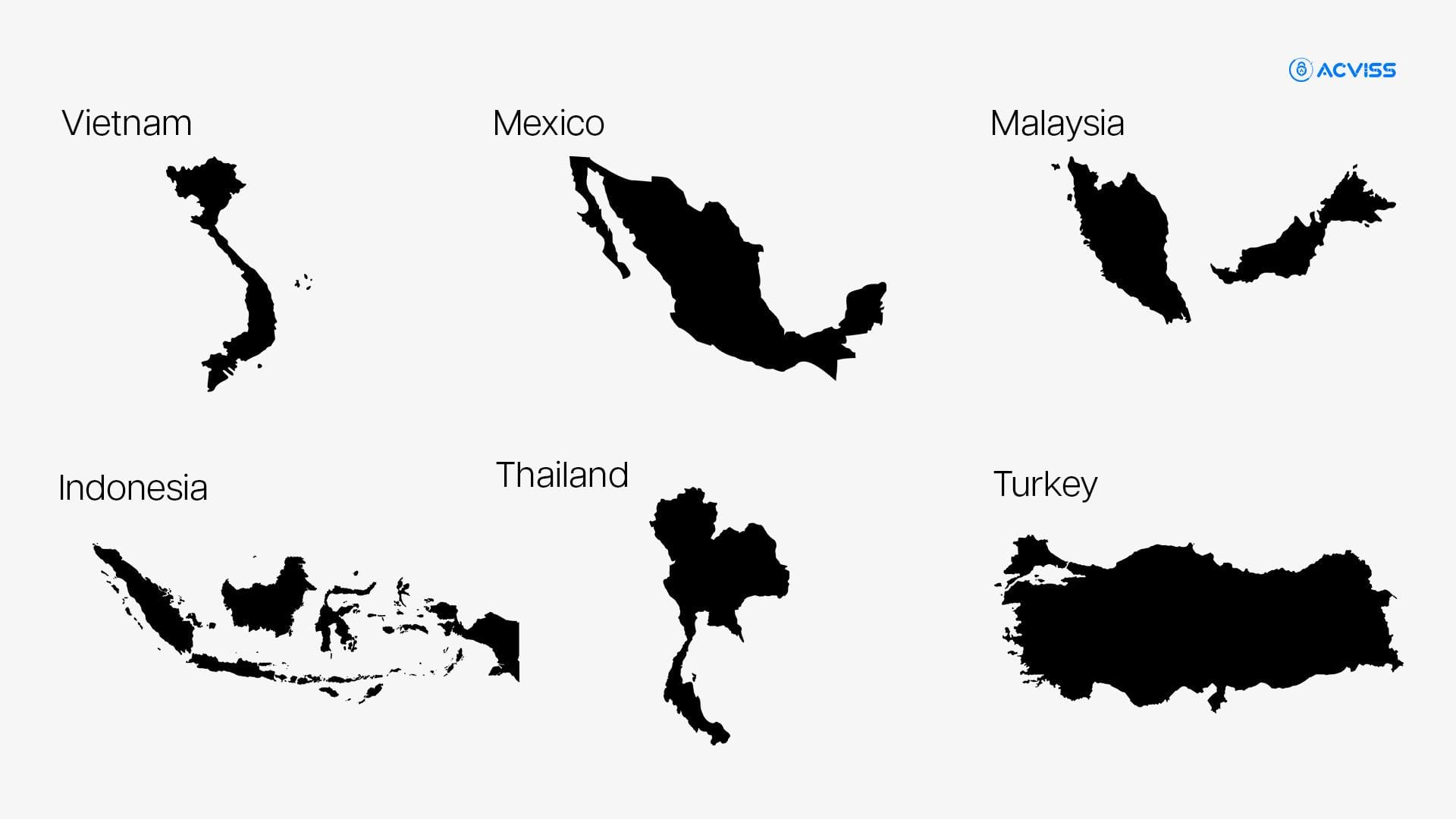

While India is the leading alternative to China, it's not the only one. Your decision may vary depending on sector, product type, and market proximity.

- Vietnam excels in textiles, footwear, and electronics, but struggles with raw material dependency.

- Mexico offers nearshoring for North America, particularly in automotive and medical devices.

- Malaysia is a strong contender in electronics and semiconductors, especially for high-tech industries.

- Indonesia and Thailand are improving in terms of manufacturing capacity and incentives.

- Turkey offers strategic access to Europe, with reasonable labour costs and decent IP protection.

Key Takeaways and Recommendations for SMBs

Deciding where to manufacture isn’t just a matter of cost. It’s a high-stakes, multidimensional decision involving risk management, long-term scalability, and strategic alignment.

Actionable strategies for SMBs include:

- Adopt a multi-sourcing model: Avoid single-point failures by diversifying suppliers across regions like India, Vietnam, and Mexico.

- Evaluate government incentives: Tap into India's PLI or Vietnam’s tax relief programs tailored for new entrants.

- Digitise supply chain visibility: Use blockchain or track-and-trace solutions to ensure transparency and traceability.

- Negotiate smarter with current suppliers: Don’t abandon China overnight. Optimise costs with existing vendors while building new relationships.

- Invest in IP protection early: Wherever you go, register patents, trademarks, and copyrights and use local legal expertise.

What’s Right for You?

So, should you manufacture in India or China?

If you prioritise cost-efficiency, democratic governance, improved IP protection, and long-term market access, India is likely your best bet.

If you require mature infrastructure, faster scale-up in high-volume production, and industry-specific clusters, China still has the edge.

But the future belongs to flexibility. The most resilient companies will not bet everything on one geography. Instead, they will craft hybrid sourcing strategies, leveraging the strengths of multiple nations, including India, China, and beyond.

India is no longer just the "next China." It’s carving its own identity as a manufacturing powerhouse, ripe with opportunity, yet requiring thoughtful engagement.

If you're preparing to make this leap, consider not just where the costs are lowest, but where your brand, IP, and operations are safest for the long haul.

Need help making your manufacturing future secure and counterfeit-proof?

Reach out to Acviss to learn how our blockchain and AI-powered solutions can protect your brand across borders, from India to China and everywhere in between.